Performance Polymers

Turning ideas into ideal solutions

At BASF Performance Materials: We turn your ideas into ideal solutions

Make Your Ideas A Reality

We combine cutting-edge solutions with established expertise to make your ideas a reality

At BASF Performance Materials, we combine cutting-edge solutions with established expertise to make your ideas a reality

- You need more than just a product to solve your challenges. You need a variety of high-performance materials, applications, engineering, simulation and manufacturing know-how to get the job done.

- Backed by our global research and development network and our team of industry-leading experts, we can help you take your product to the next level.

Key capabilities of BASF

- Close collaboration with key customers in target industries worldwide

- Innovation in products, applications, processes and business models

- Technical, engineering and application competence

- Operational excellence ensuring reliability and consistent quality

- Focused specialty businesses

Focus of research and development

Our innovation focus is on developing new products and applications in key target industries, to improve existing solutions and address new unmet market needs, particularly in developing markets with strong market potential.

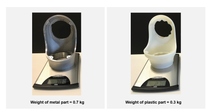

Metal Substitution with High-Performance Plastic

BASF’s performance plastics offer decisive advantages over established metal structures

BASF’s performance plastics offer decisive advantages over established metal structures in many areas. The range of applications for these intelligent plastic solutions includes automotive engineering, solar, robotics, automation and mining industries.

Vehicle construction is one particular area where BASF performance plastics have already replaced numerous metal components. BASF is now using the knowledge and know-how acquired from these projects in other markets, where plastic solutions offer prominent advantages as a metal substitute.

Metal Substitution: Our Service Package

1. Design and Construction

Parts design and construction, not only with engineering expertise but also with our Ultrasim® simulation software.

2. Manufacture and Processing

Achieving the required parts quality and establishing stable mass production.

3. Testing and Certification

Parts testing and necessary certifications to meet specific requirements and standards of each market.

4. Marketing

Support in marketing activities, leveraging on experience in automotive construction.

Bringing Designs to Life

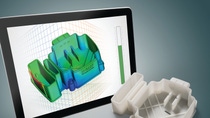

With Ultrasim®, we offer you a unique combination of core CAE tools so that each phase in the development of a component can be monitored virtually.

Beyond materials, BASF helps to develop, optimize and commercialize products faster.

Our proprietary simulation tool Ultrasim® for example, helps to select the optimal materials, as well as avoid pitfalls in tool design and production processes. This is particularly useful where the design of cobots are complicated.

Ultrasim® – CAE Competence for Your Innovative Components

When it comes to freedom of design and cost savings, plastics are often the solution. Ultrasim® is the versatile and flexible CAE competence for your innovations using BASF plastics. Our calculation of component concepts on a virtual basis starts with appropriate materials and adequate material models, ranging from the virtual prototype and ideal manufacturing process to the finished mass-produced component. With Ultrasim®, we offer you a unique combination of core CAE tools so that each phase in the development of a component can be monitored virtually.

1. Integrative simulation, material modelling

2. Thermo-mechanical modelling

3. Fatigue models

4. Mechanical material data

5. Injection molding simulation

6. Polyurethane foaming simulation

.png)

7. Static mechanical simulation

8. Dynamic mechanical simulation

9. Rheological material data

10. Mathematical parts optimization

11. 3D printing simulation

12. Creation Center