Automotive

Ultramid® Endure (PA)

Heat-resistant polyamide for automotive applications in the high temperature range

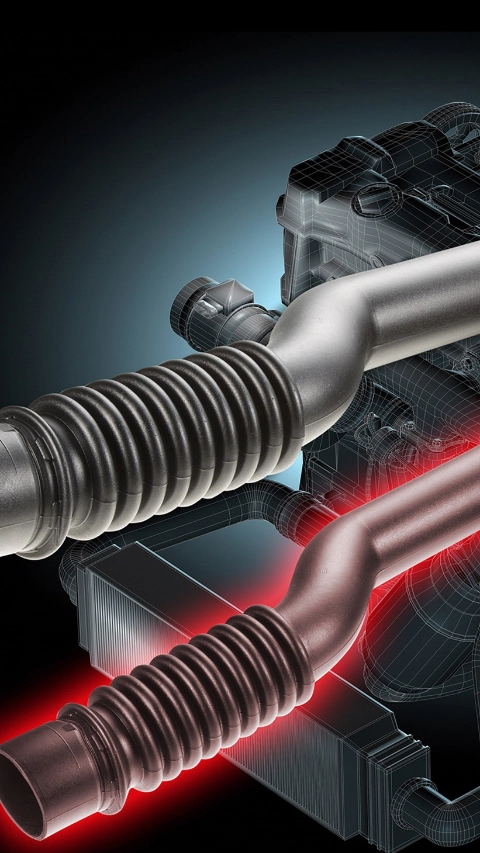

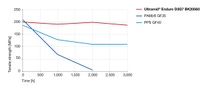

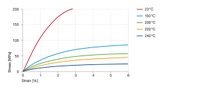

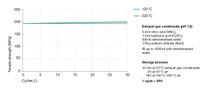

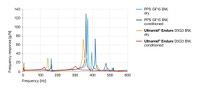

Ultramid® Endure is a glass fiber-reinforced polyamide that combines excellent heat aging resistance with the good processing properties of PA 66. Ultramid® Endure is able to withstand continuous use over 3,000 hours at up to 220°C and brief temperature peaks of up to 240°C. It thus extends the application of polyamide into the high temperature range. Ultramid® Endure is suitable both for injection molding and for blow molding. This makes the plastic the perfect replacement for metal for components used in all parts of the charge air duct ‒ from the turbocharger and pipes through to the intercooler.

Properties of the plastic resistant to hot air:

- Excellent heat aging resistance under continuous loading at up to 220°C

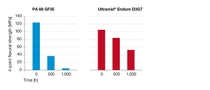

- High strength

- Excellent toughness

- Outstanding weld line strength

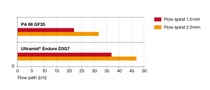

- Better flowability of the injection-molding grade than standard

PA 66 - Very good surface quality

- Excellent processability

These properties of Ultramid® Endure result in a number of advantages for processors and OEMs:

- Low system costs: lower processing temperatures, cycle time reduction, lower energy consumption, easy welding

- Continuous loading at high temperatures: durable and high-performance engines

Technical properties

Ultramid® Endure Application Range

The applications are as manifold as its product properties: Explore the various application possibilities of Ultramid® Endure!