Key advantages of Elastocoast®

- Makes coasts safer

- Porous and water-permeable

- Absorbs energy of impacting waves

- Environmentally sound

- Strong and long-lasting

Performance Polymers

Elastocoast® is a novel, intelligent polyurethane system. It is a two-component binder for revetments in coastal areas and stabilization of riverbanks. It is so open-pored that it removes the destructive energy of wave run-up, demonstrating its strength to make coasts and riverbeds much safer. Elastocoast® has also proven itself as a submerged breakwater and is ideal for marine plant restoration.

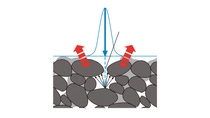

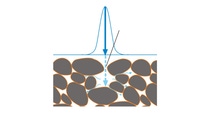

Revetments made of Elastocoast® are a new, extremely effective coastal protection system. They consist of aggregates (crushed rock) mechanically bonded with an environmentally compatible 2-component polyurethane plastic. This mixture is applied to prepared dikes, walls, breakwaters, and other marine and freshwater shorelines. The result is an extremely durable, strong, and therefore safe bulwark against waves and high water. This is achieved by distributing wave energy over a larger area, reducing the local concentration of surface pressure. Less stress is placed on the revetment. Compared to a sealed surface, which completely reflects the destructive force of the waves, the porous surface absorbs part of the hydraulic energy through friction in the pore volume and eventually converts it into thermal energy. As a result, the water masses achieve a lower wave run-up with less hydraulic energy, which reduces the potential for damage.

Stressing of a conventional concrete revetment

Elastocoast® revetments efficiently absorb wave energy

Elastocoast® makes existing dikes safer without the need to constantly raise them, which is rarely if ever possible given the financial cost and for practical reasons such as lack of space. Here, an open-pored and energy-absorbing top layer prevents the impact energy of the waves from attacking and destroying the surface, creating a higher standard of safety. Elastocoast® can also be used to repair older, completely overtopped dikes and make them safer. Normally, overtopping a levee is a dangerous scenario, as the subsequent erosion on the land side inevitably leads to a complete levee failure. Elastocoast®, however, can be applied directly to the existing revetment - without extensive pretreatment and with significantly less labor.

Normally, breakwaters are built as a concrete tetrapod. However, the toxicity of concrete and its strong alkalinity cause problems. In addition, a large yard, and a long production time (>10 days) are required, and serious dust (cement and sand) is generated. Elastocoast® is neutral to the environment. It reduces scouring and erosion and, due to its high porosity, results in lower water velocity. Elastocoast® is therefore ideal for submerged breakwaters.

Elastocoast® block

The Elastocoast® block is lowered into the water

Fishing and tourism lead to a desertification of the seas and thus to a lack of marine plants and fish. In the past, artificial reefs made of concrete were used, but they had no immediate effect. Elastocoast® provides a perfect environment for the restoration of marine plants. An Elastocoast® block placed on the seabed results in the restoration of plant life after one year. In addition, observations have shown that it leads to the return of fish and marine animals. During the observation, a 30 mm stone proved to be the most suitable for attracting life.

What has already proven successful in coastal protection can also be used on riverbanks and canals. The goal here is also to create a strong and near-natural revetment to consolidate shore zones and stabilize them against traffic-induced waves and against the tides. In waterway engineering, there is also the possibility of underwater installation where the rock-PU mix, after sufficient reaction time, is poured into the water close to the bank and compacted. The principle is just as simple as for dike construction and protects the banks from disintegration and damage due to strong currents.

The stones used must be clean and surface-dry before they are processed. This is a requirement that seems difficult at first glance. As other realized projects show, this obstacle can be overcome by simple measures in handling and logistics. Elastocoast® consists of approx. 50% vegetable fatty acid esters, thus renewable raw materials. Furthermore, it provides additional habitat for animals and plants due to the high porosity of the voids. Elastocoast® surface layers also blend harmoniously into the landscape. Due to the transparency of the material, they are virtually indistinguishable from naturally colored surface courses. Before the material has fully cured, the surface should be covered with dry sand, which can further improve the visual effect and create a non-slip surface.

Ideal substrate for flora and fauna

Biological studies by the University of Amsterdam have shown that revetments with Elastocoast® are colonized by the flora and fauna typical of the site within a few weeks. Unlike conventional, impermeable coastal protection structures, Elastocoast® revetments with their cavities also provide additional habitats for flora and fauna.

The Eco-efficiency analysis says it all

To demonstrate the environmental impact and ecological benefits of the new Elastocoast® technology, a comprehensive eco-efficiency analysis was carried out. This involved analyzing various products and processes in terms of their environmental impact over the entire life cycle. The life cycle assessment is based on DIN EN ISO 14040 and 14044 and was certified by TÜV Berlin as an overall method. Elastocoast® was compared with traditional coastal protection methods such as concrete and open stone asphalt (OSA) over an area of 20,000 m².

A study by the Institute for Environmental Hygiene and Toxicology in Gelsenkirchen confirmed the toxicological and environmental medical safety of the PU system in coastal protection. Long-term observations and checks of stability, erosion resistance, resettlement, resistance to weathering and salt water, and many other parameters have shown that Elastocoast® revetments already achieve top values in the crucial points.

Weather resistance

Hydraulic engineering structures should have a service life of 20 years or more. All construction materials on an inorganic (cement-bound) or organic (plastics) basis are subject to the influence of the weather when used outdoors. Particular attention should be paid to damage caused by UV radiation, salt water and frost. PU materials have proven themselves in outdoor applications such as the coating of concrete and sports fields or offshore, oil and gas pipelines against the influence of salt water. The degradation process that takes place in seawater has been accelerated by gradually increasing the temperature up to 80°C. In this way, the results can be extrapolated to 20-30°C. This extrapolation shows that the PU material is completely stable in salt or seawater at an operating temperature of 20-30°C and has a service life of 80-100 years. TUHH has provided evidence that there is sufficient resistance to UV irradiation, which has been tested in specially designed water-transition facilities. Frost resistance is ensured by tests according to DIN EN 13383-2.

Self-service solutions: