Plastics & Rubber

Light Stabilizers

BASF Plastic Additives is marketing a comprehensive range of solutions to mitigate plastic degradation exposed to harmful ultraviolet radiation and enabling outstanding service life duration. BASF Tinuvin®, Uvinul® and Chimassorb® ranges are the market benchmark for this core BASF expertise.

Exposure to sunlight and some artificial lights can have adverse effects on the integrity and the durability of plastics articles. UV radiation can break down the chemical bonds in a polymer. This photodegradation ultimately causes cracking, chalking, color changes and the loss of physical properties such as impact strength, tensile strength, elongation, and other properties.

Adding light stabilizers will effectively prevent polymers from photodegradation.

BASF has developed a comprehensive range of light stabilizers and UV absorbers to meet the requirements of various markets and applications such as Plasticulture or Construction.

Weathering of plastics includes, in addition to the effect of UV radiation, environmental factors like temperatures, precipitations, the presence of contaminants and others:

To counteract these damaging effects on plastics performance, a broad range of UV stabilizers designed to solve the degradation problems associated with exposure to sunlight are offered.

UV stabilizers can be categorized into Ultraviolet light Absorbers UVA and hindered amine light stabilizers HALS:

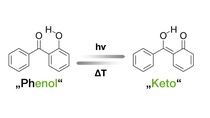

UVAs slow down the degradation process by preferentially absorbing harmful ultraviolet radiation and dissipating it as thermal energy.

UV Absorbers are therefore effective

- at protecting the polymer bulk,

- at protecting the content when used in packaging films or bottles,

- at protecting other additives, more sensitive to UV light (e.g. pigments and flame retardants),

- in UV absorbing substrates, such as polystyrenes, polyesters, etc.

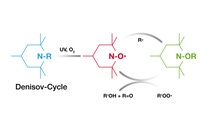

HALS are very efficient stabilizers for polymers and especially polyolefins. They do not absorb UV radiation, but inhibit degradation of the polymer by scavenging radicals. Significant levels of stabilization are achieved at relatively low concentrations. HALS' high efficiency and longevity are due to a cyclic process wherein the HALS are regenerated rather than consumed during the stabilization process.

HALS are therefore

- very effective in high surface area applications such as film and fiber,

- the most effective additive for the light stabilization of polyolefins,

- also highly effective thermal stabilizers for longer polyolefin articles service life.

UV Absorbers: Converts UV Light Into Heat

Hindered Amine LS: Deactivation of Free Radicals

Light Stabilizer portfolio

Chimassorb® 81

Chimassorb® 944

Chimassorb® 2020