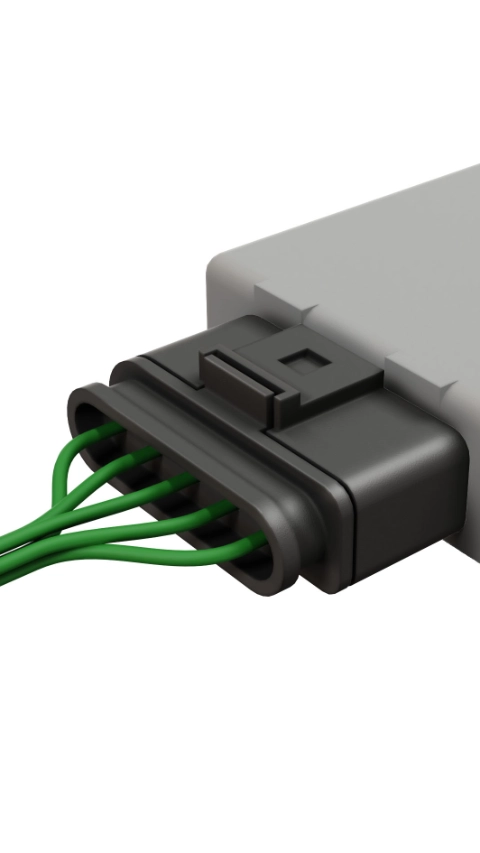

Automotive

Ultradur® HR – PBT for challenging environments

Long life under demanding conditions

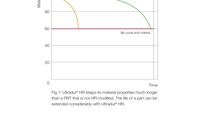

The main feature of the Ultradur® product range with the suffix HR (=hydrolysis resistant) is the extremely high resistance of the PBT polymer (PBT=polybutylene terephthalate) to damage due to water at elevated temperatures.

Contact with water in polyesters, even in the form of atmospheric humidity, leads to hydrolytic cleavage of the polymer chains and thus to a weakening of the material, particularly at elevated temperatures.

Ultradur® HR is based on standard PBT, but incorporates highly effective additives which greatly retard the hydrolytic degradation and can therefore considerably extend the life of a part.

Higher demands for plastics applications

For critical applications such as those in automotive electronics, long life and reliability are basic requirements. It is often possible that the average operating temperature in modern electronic components increases, e.g. due to compacting.

It is also possible that the components are used where they are exposed to the waste heat from the drive system to a considerable extent. Naturally, the plastic parts should be functional in all climate zones on earth, even in damp hot conditions.

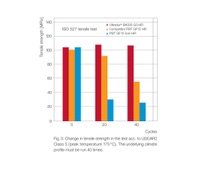

If spray water and road salt play a role, this can also increase the demands on the plastic. Therefore, the level and duration of the stress are key factors as to whether or not an application is feasible using a PBT without improved hydrolysis resistance.

Today, the specifications for a number of plastic applications in the automotive sector include tests at elevated temperatures and humidity or tests on changing climatic conditions. These tests can only be passed by HR-modified PBT grades.

Ultradur® HR combines hydrolysis resistance with stable processing

Ultradur® Application Range

The applications are as manifold as its product properties: Explore the various application possibilities of Ultradur®!