Plastics for Furniture

Cellasto® adds premium-quality comfort to office furniture

Today’s office workers spend more time at their desks than ever, which is why the demand for premium furniture is at an all-time high. When you add Cellasto® to furniture components such as suspensions and springs, this high-performance elastomer will win over the most selective customers.

Why Cellasto® is the solution for premium-quality furniture

Rely on BASF’s team of global experts to help you engineer designs that meet precise specifications for both ergonomics and comfort while preserving the integrity of your design aesthetics. With locations worldwide, BASF is your partner for providing custom-designed furniture components created with the unique versatility of Cellasto®.

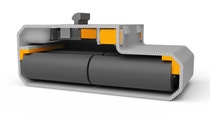

Suspensions and spring elements

Sedentary employees are becoming more creative multitaskers, often incorporating movement while sitting at their desks.

-

Add Cellasto® to springs involved in suspensions to create a smoother, side-to-side movement

-

Replace metal springs with Cellasto® springs to avoid clicking noises in buttons and release valves in headrests and armrests.

-

Extend the life of your components with this material’s superior abrasion resistance

Friction dampers and end stops

When you place Cellasto® friction dampers and end stops in furniture, your customers can enjoy the peace, relaxation and concentration they need and deserve.

-

Avoid rough, sudden movements upon adjusting armrests and chair height

-

Soften the sound of cabinet and desk drawers opening and closing

-

Achieve optimal damping, regardless of chair load capacity

Cellasto® ensures lasting comfort and durability

Your Cellasto® furniture components will meet today’s expectations of smooth movement with no grating sounds. Find creative freedom and limitless possibilities when you co-create custom solutions with BASF’s team of experts. You will be able to create the unique designs you want while attaining the premium level comfort and convenience your customers expect.

Excellent energy absorption

The dynamic performance of Cellasto® allows you to manage kinetic energy at high and low amplitudes with a single material. The progressive load-deflection curve of this high-performance material means that when you add it to end stops, customers can raise and lower their chairs without jarring starts and stops.

Low compression set

The high compressibility and low compression set of Cellasto® allows you to fit furniture parts into tight or unusual spaces. As the microcellular material compresses, there is very little lateral expansion, which means the components are smaller and lighter. This facilitates the handling efforts for you and makes the product less cumbersome for the customer.

Flexible, strong and durable

Premium products should be built to last. Extend the life of your furniture when you use Cellasto® to create various components. This material’s dynamic strength has excellent aging stability, ensuring your furniture can stand the test of time.

BASF: Your global partner in furniture solutions

The Cellasto® team helps you keep pace with the higher expectations your customers have for the furniture industry. Count on BASF as your partner for:

-

Development, simulation and testing to help you refine your design

-

Certified furniture components that assure compliance with standards

-

Global reach that shortens your acquisition time

-

New technologies you can leverage for market advantages

-

Efficient, worldwide supply chain management that ensures maximum value

-

Commercial support that enhances business development and profitability

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.