Performance Polymers

Elastocool® (PU) - Ingeniously flexible and modular

Elastocool® is a pentane-based polyurethane rigid foam system for insulating refrigerators and freezers. Elastocool® offers maximum productivity coupled with extremely low material consumption and delivers improved energy efficiency.

The fast insulation solution for fridges and freezers

Elastocool® F

The fast insulation solution for fridges and freezers

Elastocool® F is the new high-performance PU insulation foam from BASF for the refrigeration industry. This pentane-blown system offers maximum productivity combined with low material consumption and improved energy efficiency. This cutting-edge insulation technology has been developed using a completely re-engineered raw material set and facilitates a robust foaming process.

Fast demolding is the key word for high productivity

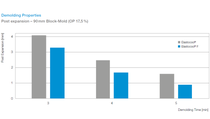

A polyurethane rigid foam is the solution of choice when it comes to insulation of refrigerators and freezers, as these materials offer the highest level of thermal insulating properties. The demand for fast demolding has increased in importance in order to be able to save energy and to enhance productivity. The BASF R&D-Verbund consequently focused on this as one of the key features for the new generation of Elastocool®. Elastocool® F boosts the capacity of foaming lines and adds flexibility to the production process. Additionally, the mechanical properties have been significantly improved, enabling a lower overall material consumption.

Product properties and benefits at a glance

- Significantly reduced post expansion leads to faster demold cycles

- Capacity increase of existing foaming equipment without investment

- Improved energy efficiency derived from better thermal insulation properties and potential increase of wall thickness without compromise in productivity

- Lower material consumption due to high structural stability

- Excellent surface quality

- Improved sustainability according to life cycle assessment

Consult with an expert

Self-service solutions: