Performance Polymers

Cellasto® delivers superior automotive NVH solutions

Reduce noise, vibration and harshness (NVH) in a wide range of automotive applications with Cellasto®, the industry’s best known microcellular and compact polyurethane elastomers. By working together with you, the BASF team of experts will create solutions that meet and exceed your expectations for market-ready automotive products. Because Cellasto® properties can be engineered, it’s ideal for multi-material applications that extend the limits of automotive design.

Why automotive innovators choose Cellasto®

Today’s automotive trends demand material and design innovation as well as reliable serial production. From eMobility and modern vehicle dynamics to safety standards and value-chain improvement, Cellasto® has been the Performance Material of choice for automotive innovators worldwide for over 60 years.

Cellasto® Global Competence

BASF and the Cellasto® team support your innovations from conception to serial production. Count on BASF as your partner for:

- Simulation and testing to help you refine your design

- Global reach that shortens your development time

- New technologies you can leverage for market advantages

- Finished and semi-finished parts that accelerate and simplify your solutions

- Efficient supply chain management that ensures maximum value

- Commercial support that enhances business development and profitability

Guaratingueta in Brazil

Manufacturing site

Start of production in 2013 and the Cellasto production in Brasil started in 1984

Lemförde in Germany

Manufacturing site and regional technical center

Start of production in 1961

Wyandotte, MI in North America

Manufacturing site and regional technical center

Start of production in 1986

Shanghai in China

Manufacturing site and regional technical center

Start of production in 2010

Dahej in India

Manufacturing site

Start of production in 2014

Cellasto® is the primary material for thousands of automotive components currently in production across the globe. Discover the open road of innovation with Cellasto® and all its possibilities.

Life is one smooth ride with Cellasto® NVH solutions

Discover the superior properties of Cellasto®. From its NVH improvement to its damping effects, vibration control and beyond, Cellasto® outperforms and outlasts traditional materials for automotive applications.

NVH Improvement

Oscillations that come from the roadway or the automobile’s chassis and powertrain cause noise, vibration and harshness effects. Vehicle components designed with Cellasto® efficiently hinder the transmission of NVH into the passenger compartment, resulting in a smooth, comfortable ride. Cellasto® is engineered to minimize NVH in a variety of interior applications as well, ensuring a superior driving experience.

High Compressibility

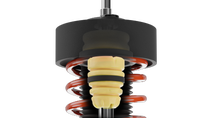

The cell structure of the microcellular polyurethane elastomer means it can be compressed more than traditional materials. For automotive applications, the nonlinear progressive characteristics of Cellasto® offer high load capacity in a limited volume space, allowing for smaller assemblies that fit in tight spaces, such as jounce bumpers and top mounts.

With the impressive package gain compared to traditional materials, you can count on less material waste, which offers more value. A smaller installation means greater cargo volume in the rear of the vehicle as well as improved crash safety under the hood or more space for other functional components like shock absorbers.

The compressibility of Cellasto® also allows for progressive load-deflection behavior, from initial acceleration through full stop of the vehicle, resulting in a smoother ride and ease of operation.

Lightweight

Improve the automotive value chain by taking advantage of the lightweight properties of Cellasto®. Because it is less dense and allows for reduced volume requirements compared to traditional materials, Cellasto® reduces weight by up to 30% per part. Additionally, your lighter, more efficient vehicles will require less fuel or battery power, making them a better choice for climate protection.

Dynamic Performance

The amplitude selective damping of Cellasto® offers the best of both worlds: High-amplitude damping absorbs the energy of the system for excellent vibration control, even on rough road surfaces. Low-amplitude isolation cushions the structure borne noise, so the automobile’s interior is exceptionally quiet and comfortable for drivers and passengers. This combined vibration and acoustic isolation performance is especially valuable for e-Mobility applications where road noise is a more critical factor.

Soft and Durable

With durability that lasts for the entire lifetime of the automobile, Cellasto® outperforms traditional materials. Its resistance to low temperatures, heat, ozone, microbes and moisture means components endure for an extended life span. Because it maintains its softness, strength and NVH properties, Cellasto® promises greater value overall. As a versatile choice for high-performance automotive applications, Cellasto® properties can be isolated and manipulated through creative chemistry, allowing for precise softness that fits your specifications.

Superior Material Choice

Compared with other materials, the polyurethane foam cell structure of Cellasto® provides the consistency you need for reliable performance throughout your serial production process. Customized Cellasto® solutions offer you the design freedom you need for your applications as well as practical advantages throughout the automotive value chain.

Cellasto® solutions achieve a long service life with excellent durability that delivers better value. BASF’s worldwide production facilities bring Cellasto® solutions close at hand, allowing you to maintain production.

Cellasto® automotive applications

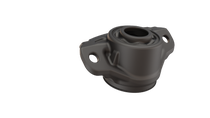

Enjoy design freedom for your automotive applications with the versatility of Cellasto®. Install this high-performance elastomer in automotive components as an improvement over traditional materials.

Additional Resources

Explore our knowledgebase of brochures, videos and other resources like our services page to expand your engineering insight and spark your creativity.