Performance Polymers

Cellasto® friction dampers for longer lasting smooth performance

“Smooth” and “quiet” aren’t always associated with high production, but they should be. Those characteristics increase the performance and the quality of your products, which is why today’s innovators are adding Cellasto® to friction dampers in a wide variety of merchandise, ranging from various appliances to automotive interiors.

What is a friction damper?

Friction dampers absorb the energies of unbalanced masses and corresponding large vibrations by converting motion to heat. Utilized in this application, Cellasto® has proven superior at reducing noise and vibration while increasing performance, extending life and streamlining design and manufacturing processes.

Due to a permitted high pre-load assembly and volume compressibility, it is predestinated for friction (lining/surface/coats). This means it allows for a more consistent and smooth operation under a wider range of demanding conditions compared to traditional materials, such as non-foamed elastomers or metal alloy.

Moreover, Cellasto® friction lining/surface/coats can compensate for assembly tolerances, are not sensitive to variations in temperature or dust and debris on surfaces and offer an elastic support of moving parts.

A little bit of Cellasto® goes a long way, so it doesn’t have to break your budget. When you use it in friction dampers for automobiles, agricultural equipment, office furniture, various appliances and power tools, your team will gain a competitive edge in the global marketplace by increasing its values.

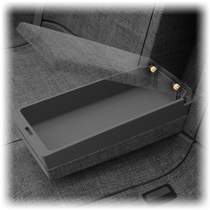

See Cellasto® friction dampers in action

Ways to use Cellasto® in friction dampers

To maximize NVH performance, your team can utilize Cellasto® in a number of friction damper applications. Here are a few areas in which Cellasto® has become the insider’s secret to higher quality solutions:

Join a global group of innovators

By utilizing Cellasto®, the insider's secret for increasing performance, companies stay a step ahead of the competition.

The co-creators at BASF will help you capitalize on the versatility of Cellasto® and your creativity to design custom solutions that fit your product specifications.

From the design to product testing to continuously improving your innovations as they evolve, we can ensure you consistently deliver the high-quality, safe products that your customers demand and deserve.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.