Automotive

Cellasto®: A flexible solution for a wide variety of tolerances

Adapting to life’s imperfections can be a challenge sometimes, but it shouldn’t be in your products. Using Cellasto® washers and end stops for tolerance compensation can significantly reduce noise, vibration and harshness (NVH). Superior compressibility and resilience make it the material of choice for innovators around the globe in designing tolerance compensation elements.

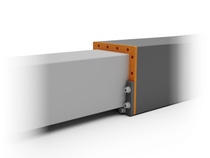

What is a tolerance compensation element?

When components are fit together, manufacturing variability (or tolerance) requires adaptive compensation to ensure proper connections and operation. Otherwise, your products will produce rattling sounds and unnecessary vibrations associated with inexpensive products.

The resilience and extremely high compressibility of Cellasto® make it an outstanding material for compensating for a variety of production and assembly tolerances, enabling it to outperform other elastomers in reducing NVH as well as extend the product life and lower the production costs.

See Cellasto® tolerance compensation in action

Ways to Use Cellasto® in tolerance compensation

When you add washers, end stops and motion guides made with Cellasto®, you create a more efficient design for products with kinematics such as:

Creative & customized solutions for challenging specifications

The flexibility of Cellasto® for tolerance compensation allows you more freedom as an innovator while saving on production costs. As your co-creators, the team at BASF can help you create unique products, regardless of the specifications, and give your product a competitive edge.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.