Performance Polymers

Circularity and recycling with BASF

Our goal is to move towards a more Circular Economy, using more and more recycled and renewable raw materials, shaping new material cycles and creating new business models. BASF has therefore launched a new Circular Economy Programme: CIRCULAÍ

But what is Circular Economy?

By 2022, only 14% of the world's plastic is recycled, with 8 million tonnes of plastic ending up in the oceans annually."

With this in mind, the Performance Materials team launched the program:

CIRCULAÍ

Get to know the BASF Circular Economy Program, for the collection and reframing of polyamide waste 6 and 66.

Get to know CIRCULAÍ

But how does CIRCULAÍ works?

With a team of experts in resource reuse, salvage, and process improvement, the program prepares customers and partners to experience the circular economy and recycling in practice.

In line with its purpose to create chemistry for a sustainable future, BASF now presents a portfolio of polyamides with recycled content, contributing to the circular economy in the plastics world.

Benefits

What do we have to offer you?

- Redefine the scrap, paying a fair price that stimulates business

- Traceability and reliability for the destination of the material

- Participation in an innovative model for engineering materials in Brazil

- The entire structure for collection, chartering and availability of materials

- Structure to assist in goal setting, training and support

How to be part of CIRCULAÍ?

Provide scrap

The partner will go through the qualification and training phase and, upon approval, will be integrated into the program. Together we will understand where the waste is generated in the injection process.

• What materials will be collected: only the polyamide waste (can be PA 6 and PA 66, with or without cargo), which can be packed in big bags or 25kg sacks.

• How the materials will be collected: after alignment with the person responsible for your unit, we will purchase the scrap and provide transportation for removal. At least 1 ton of material will be required for the removal to occur.

Buy recycled material mechanically

Come join our program! BASF has a broad portfolio of mechanically recycled products in polyamides 6 and 66 (Ultramid®).

Learn more below!

Program portfolio of CIRCULAÍ

Due to its numerous features, with Ultramid®, many applications are possible, such as:

- Automobile Construction

- Electrical and electronic components

- Consumer goods, among others...

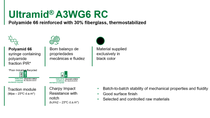

Virgin polyamide 66 with mechanically recycled polyamide from scrap collected in the CIRCULAÍ program:

Benefits of Ultramid® A3WG6 RC:

- Material with less use of fossil sources.

- High performance and circular.

- Reliable stability from batch to batch.

- Contribute to the reinsertion of scrap into long-life applications.

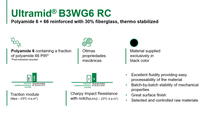

Polyamide 6 + 66 reinforced with 30% fiberglass, thermostabilized

Benefits of Ultramid® B3WG6 RC:

- Stability of mechanical properties and fluidity from batch to batch.

- Good surface finish.

- Selected and controlled raw materials.

See more BASF Solutions for your business:

Consult with an expert

Self-service solutions:

.jpg)