Key Advantages of Ultraform®

- High rigidity and stiffness

- Good resilience properties

- Excellent resistance to chemicals

- Excellent sliding friction properties

- Low water absorption and tendency to creep

- Dimensional stability

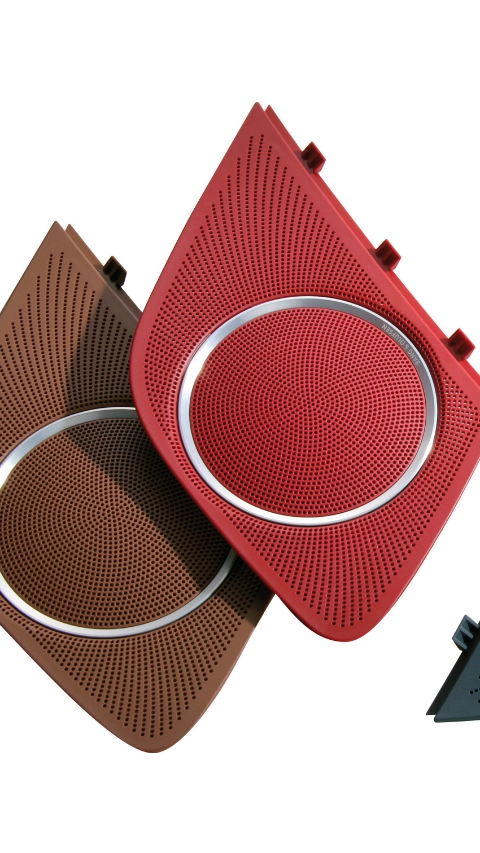

Automotive

Ultraform® is the brand name for BASF’s polyoxymethylene product range. It comprises engineering plastics designed for use in sophisticated components. Ultraform® is suitable for many applications in automotive manufacturing, in medical technology, for household and recreation, but also for machine and plant construction.

Ultraform® can be thermoplastically processed and has a partially crystalline structure with a high degree of crystallization. It is produced by the copolymerization of trioxan and another monomer. It consists of linear chains in which the co-monomers are firmly incorporated in a statistically distributed manner. These co-monomer units account for the high stability of Ultraform® during processing and when exposed to long-term heat and to chemicals. It surpasses by far the resistance of homo-polymeric polyoxymethylene.

Ultraform® can be processed by all methods suitable for thermoplastics. The most important methods are injection molding and extrusion. Injection molding allows even the most complicated moldings to be mass-produced very economically. The extrusion process is used to manufacture rods, pipes, profile sections and sheet, most of which are further machined by means of cutting tools to form finished parts.

The Ultraform® product line encompasses grades for processing by means of extrusion and injection molding. The following product groups exist:

The applications are as manifold as its product properties: Explore the various application possibilities of Ultraform®!

We offer our customers a comprehensive range of services with leading technologies and products. Find the service that matches your needs!

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.