Performance Polymers

Ultrasim® Mechanical Simulation

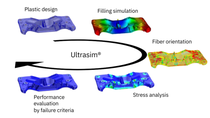

The core model of Ultrasim® allows for a broad range of analyses, from crash to creep, from humidity related swelling to thermomechanics. For some special analysis types, like fatigue, humidity diffusion or linear dynamics, specialized Ultrasim® material models are available.

Highspeed Crash Simulation

Crash loadcases and drop tests are characterized by high strain rates and failure of the material. Ultrasim® offers material models which can cover these effects. This allows a precise prediction of a crash event and the development of a predictable, robust, and controlled failure behavior. Examples for the use of these material models in serial applications are crash absorbers and all kinds of crash loaded parts:

.png)

Quasistatic Simulation

Quasistatic simulation can be conducted with constant or transiently calculated strain rates, with inhomogeneous and transient temperature and humidity distributions, and with or without individual material behavior for welding lines. Fiber orientation can be mapped from process simulation like Moldflow® or Moldex3D or be simulated directly within Ultrasim®. Even with implicit solvers like Abaqus or Ansys, post failure behavior can be examined.

Creep and Relaxation Simulation

The Ultrasim® material model includes rupture at tertiary creep. It comes with the same features as the standard load carrying analysis.

Thermomechanical Simulation

Thermomechanical simulation takes anisotropic, nonlinear Coefficient of Linear Thermal Expansion (CLTE) into account. Inhomogeneous temperature distribution and anisotropic heat transfer can be covered if needed. As heat transfer in plastics occurs slowly, creep can play a role in these loadcases and can be covered by the material model.

Simulation of Humidity Uptake

The diffusion simulation for the water uptake can be coupled transiently with the simulation of resulting swelling. The diffusion simulation can be performed separately and the humidity distribution is mapped to the swelling simulation model in the same way as the fiber orientation data.

Consult with an expert

Self-service solutions: