Construction

Infinergy®(E-TPU) is Empowering Movement

We are accelerating with the world's first expanded thermoplastic polyurethane (E-TPU). With Infinergy®, we help game changers and go-getters move ahead in life. We empower workers to move like athletes, children to play more safely and athletes to perform at their best.

Infinergy® provides superior energy return while delivering a lightweight, high strength alternative. Infinergy® adds next-level comfort and flexibility in a variety of applications ranging from footwear to flooring to sports equipment.

Check out the all new Infinergy® Virtual Showroom

How can Infinergy® benefit you?

Applications

Properties

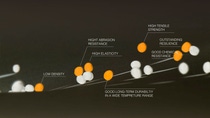

Like its base material TPU, Infinergy® is noted for having high elongation at break, high tensile strength and strong abrasion resistance. In addition, the innovative particle foam remains highly elastic and soft over a wide temperature range. It is also made out of material that has good chemical resistance.

The feature of Infinergy®’s that is particularly striking is its high resilience.

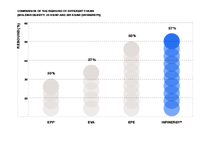

Tests of its resilience elasticity under ISO 8307 (the ball rebound test) show that Infinergy® achieves a rebound of over 57 %. This is therefore significantly higher than comparable particle foams such as expanded polypropylene (EPP) at 30 %, ethylene vinyl acetate (EVA) at 37 % or expanded polyethylene (EPE) at 50 %. Infinergy® maintains its excellent resilience even under a continuous load.

Measuring the rebound according to DIN 53512 (using a defined pendulum hammer), a rebound value of at least 57 to 75 % is achieved. Dynamic mechanical analysis has shown that, even at extremely low temperatures of -20°C (-4°F), Infinergy® still has a low dynamic modulus, is very soft and stretchy and thus does not go stiff.

Processing

Infinergy® 32-100 U10 is processed on the usual commercial steam chest molding machines designed for a minimum steam chamber pressure of 5 bar.

Steam pressures are typically 0.6 – 2.2bar, depending on the Infinergy® grade as well as part geometry and density. Infinergy® 32-100 U10 is processed by either crack filling or pressure filling, so part densities of 200kg/m3 to about 300kg/m3 are achievable depending on the degree of packing. Infinergy® can also be processed by molding technologies not using steam e.g. high frequency and variotherm molding.

In addition, because polyurethanebinders adhere so well to Infinergy®, processing techniques such as gluingand foam sealing of the beads enables large-scale processing of Infinergy®.

Converters can process panelsmade from Infinergy® on conventional splitting machines, punches and water jet cutting machines.

Environment and Recycling

Infinergy® is compliant with the RoHS directive and does not have to be labeled under dangerous goods regulations.

Information on other regulations, e. g. GADSL, will be provided on request.

Infinergy® is also recyclable.

News

BASF's new technology for E-TPU allows for endless design options to be realized in short cycle times

Publication release date: November 30, 2023

For more than 40 years, BASF is a leading supplier of tailor-made high-performance footwear materials for all types of shoes and soles. With our portfolio of polyurethane systems (PU), thermoplastic polyurethanes (TPU) and engineering plastics, we offer leading companies in the footwear industry an integrated toolbox of solutions which is unique. Next to our deep material expertise, we also have an intimate understanding of the value chain; from raw materials supply and production to how to attach the shoe sole.

In general, shoes comprise an upper and a sole made from several components, for example a midsole and an outsole. Depending on the specific type of shoe, different properties are needed. From protective needs to cushioning or high grip, different materials are used to manufacture shoe soles. For example, ethylene-vinyl acetate (EVA) allows for good cushioning properties, while thermoplastic polyurethane (TPU) is known for providing strong abrasion resistance.

Infinergy® is the world's first expanded thermoplastic polyurethane (E-TPU) used in midsoles making the shoe comfortable to wear and delivering excellent running properties. E-TPU midsoles are conventionally produced on steam chest molding machines with pressures of about 0.6 to 2.2 bar and steam temperatures in the range of 110 to 130°C.

BASF recently introduced storable thermoplastic particle foams, having a polymeric surface functionalization (see news below). This functionalization offers a wide range of novel properties and enables the efficient production of parts like midsoles in conventional compression molding machines, i.e., under heat and pressure without the need of steam. The loading of the mold with these novel surface-tuned foam particles can be done manually but preferably automatized with at least one feeding line and the aid of e.g., compression air.

The molding conditions depend on the surface functionalization and/or the expanded thermoplastic material. With E-TPU, molding temperatures in the range of 100 to 150°C and molding time between one and 30 minutes are usually applied. The characteristics (like density) and the properties of the molded parts can be influenced by varying the compactaction of the beads, the heat, the molding time and the cooling time, before demolding of the desired part. With the heat treatment and the adequate mold surface, it is also possible to texturize the surface of the molded part without significantly changing the overall properties. Thus, endless designs of the surface of midsoles can be realized, for example also grid-shaped design.

Shoe soles components such as midsole, outsole and other functional elements are usually manufactured separately and then subsequently glued or sewed together. With BASF’s surface-treated thermoplastic particle foams, it is now possible to combine different kind of materials (EVA, rubber, thermoplastic materials) and/or different thermoplastic particle foams (different mixture of E-TPU, E-TPS, E-PS, E-PP, E-TPA, E-TPC, E-TPO) and/or embed inserts in one processing step.

This new technology from BASF is not only limited to compression molding, but also well suited for other molding processes like RF and steam chest molding. This innovation facilitates tailor-made design of shoe soles in short cycle times with a lower environmental footprint.

Broader processing spectrum accessible by novel surface tuning of foam particles

Publication release date: June 29, 2023

BASF will soon introduce particle foams with a polymeric surface functionalization that provides access to a variety of molding processes, such as hot pressing, RF welding, and other molding technologies. In a novel process, the particle foams are provided with a uniform polymeric surface functionalization. The treated foam particles are storable and can be fused into molded parts in a much more energy-efficient and material-friendly manner. The novel surface-tuning can be applied to almost all material classes, such as expanded particle foams made of thermoplastic polymers, thermoplastic polyurethanes and thermoplastic elastomers. With the surface functionalization it becomes possible to combine different kind of materials as well as to embed inserts, and, therefore obtain a tailor-made design of molded parts in one processing step.

News Archive

Infinergy sprints ahead in the indoor fitness space with Keep’s latest treadmill

BASF launches “Empowering Movement” brand strategy for Infinergy

New size, new color, new processing method – Infinergy® picks up the pace

BASF receives top 10 “Sports Surfaces Materials Supplier” award in China

Plymouth Foam to launch a new generation of pet toys at SuperZoo 2019 based on BASF Infinergy material

Tailor-made Solutions

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.