Performance Polymers

Cellasto® reduces NVH for improved elevator operation

Meet today’s standards for elevator comfort with Cellasto®. This high-performance microcellular polyurethane elastomer reduces noise, vibration and harshness (NVH) ensuring your elevators offer passengers a smooth, quiet ride.

Why innovators choose Cellasto® for elevator applications

BASF is your experienced partner in the elevator industry, providing custom-designed and safety-certified components crafted with the outstanding versatility of Cellasto®. Count on BASF’s team of global experts to help you engineer designs that meet your specifications for NVH, safety and performance.

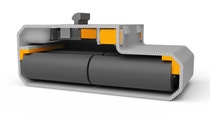

Engine bearing

Control noise and vibration NVH produced by the elevator’s engine with Cellasto®. Cellasto offers outstanding vibration isolation and long-term durability.

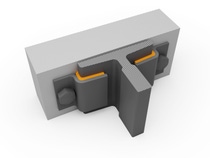

Cabin isolator

Reduces the vibration of the pulley beams by decoupling the passenger cabin from the elevator’s hoisting mechanisms.

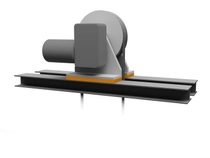

Rail isolator

Avoid the transmission of operational vibration into the building structure with Cellasto® rail isolators. Design a custom solution to fit your guide rail fixing method.

Rope buffer

Control acceleration peaks with Cellasto® rope buffers at cabin and counterweight during starting and stopping movements.

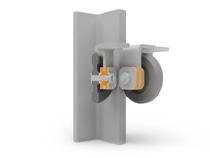

Roller guide mounts

Keep wheels in position and isolate the elevator’s passenger cabin from noticeable wheel vibration. Reduce cost and weight by a simple, customized Cellasto® solution.

Cellasto® ensures smooth, quiet elevator performance

Your Cellasto® elevator components will meet today’s expectations of smooth, quiet motion that communicates high-quality performance. With custom solutions co-created with BASF’s team of experts, your innovations will know no limits.

In elevator components where dynamic forces are at work, Cellasto® decouples the critical contact points. Even in small spaces, Cellasto® ensures excellent acoustic and vibration damping. Isolate the passenger cabin and building effectively with Cellasto® as your most versatile solution to reduce NVH.

Cellasto® components offer the following advantages:

- Excellent static and dynamic long-run behavior

- High-volume compressibility with minimal lateral expansion

- Low dynamic hardening and amplitude-selective damping

- Low compression set

- High-abrasion resistance

- Excellent for energy absorption

- Resistance to cold, heat and moisture

- Resistance to oil, grease, ozone and other important media

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.