Performance Polymers

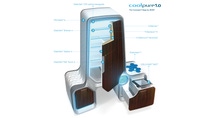

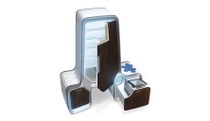

coolpure 1.0: Fridge of the Future

Innovative materials, functionality and futuristic design: The concept fridge coolpure 1.0 demonstrates the versatility of polyurethane materials of our product portfolio. The result of this design study? The fridge is neither white nor square and does much more than refrigerate.

We Innovate to Make You More Successful

Reinventing the well-known is the idea behind the concept fridge. As an outcome of the design study coolpure 1.0 the household device changes into a technological piece of furniture. For a long time, it has not varied a lot in shape or color, but this fridge now offers lighting and seating in addition to the cooling function. This is achieved through the use of ten innovative polyurethanes. The fridge consists entirely of the material, which is currently mainly used for insulation. "With coolpure 1.0 we would like to show the diverse possibilities for future materials and designs, exploiting the versatility of polyurethanes," explains Project Manager Dr. Nils Mohmeyer.

The Concept Fridge coolpure 1.0

The Materials of the Visionary Household Device

The used polyurethane materials allow design that is anything but standard: instead of white and square, exceptional shape and color have been achieved for coolpure 1.0. Furthermore, the design study illustrates that innovative materials can also be used for specific conditions such as the inside of a refrigerator. Discover the materials!

COLO-FAST® WST®

The encapsulation material COLO-FAST® WST® ensures a pressure-less application of the glass of the freezer drawer. The Window Spray Technology is seal and surround in one and provides perfect smoothness of seal and glass.

Elastofoam® I

With its both flexible and elastic properties, Elastofoam® I delivers remarkable comfort for the seating elements of coolpure 1.0. The pleasant feel and good skin formation transform the purely functional refrigerator into an impressive piece of furniture. Thanks to its excellent flow, the system is also capable of replicating complex textures in all imaginable shapes or colors – high design freedom is thus always assured.

Permaskin®

The exterior and interior surfaces, including the bottle rack, are coated with Permaskin®. These flexible films based on thermoplastic polyurethane elastomers refine the surfaces and contours of coolpure 1.0 and provide protection as well.

Elastollan® Soft Touch

The door handle is made of Elastollan® Soft Touch providing a very pleasant touch. The aliphatic, thermoplastic polyester polyurethane is highly light- and colorfast, and renders additional coatings superfluous. It also shows impressive resistance to abrasion and scratches.

Elastollan® LED Optical Waveguide

For the interior lighting and the external light strip "ambient light" flexible optical waveguides made of Elastollan® have been implemented. The light is particularly soft, economical and available in any color. The waveguides are crystal-clear and highly amorphous, allowing for an extremely low dimming of light. Surfaces can be manipulated in order to achieve controlled light effects.

Elastollan® Gasket

The sealing profiles made from Elastollan® provide outstanding hydrolysis resistance and cold flexibility. Because the thermoplastic polyurethane is resistant to microorganisms, it can be used for the extrusion of profiles and continuous seals as surrounds.

Elastocool® Advanced

Elastocool® Advanced has outstanding thermal insulation properties, which means another cut in energy consumption. The significant reduction in demoulding time boosts the capacity of the foaming line and adds to the flexibility of the production process. The system’s compression resistance has been additionally enhanced, thus making it possible to reduce density and hence the input of material.

Elastollan® Shelves

The shelves are made of thermoplastic polyether polyurethane and distinguished by their excellent hydrolysis resistance and cold flexibility. Good thermoform properties allow for extraordinary designs. Elastollan® is highly transparent, even in thick walls. There is an extra optical effect, as the shelves of coolpure 1.0 light up with light from rear-mounted LEDs, which is emitted at the cut surfaces.

Elastopor® H

Elastopor® H ensures energy efficiency. The open-celled rigid foam Elastopor® H has a low density and very high compression strength, making it especially suited to the production of vacuum insulation panel cores. The PU rigid foam can be produced in precisely contoured panel forms and easy to process.

Balindur™

For high standards of energy efficiency of coolpure 1.0 Balindur™ was used for fixing insulation panels. The polyurethane foam is not only adhesive, but also compensates for unevenness in the substrate. The panels are invisible from the outside.

10 Steps Towards a Cool Future

Consult with an expert

Self-service solutions: