Advantages of Elastofoam® I:

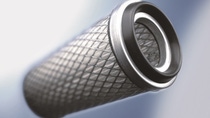

- Decorative surface finish, high abrasion resistance

- Resistant to mechanical stress and chemicals

- Elastic even after continuous stress

- Added layer of water-based in-mold coating can be incorporated to provide UV-stability and multi-tone color options

- Low thermal conductivity

- Cost-effective, One-shot processing for foams with integrated, attractive surface