Performance Polymers

Cellasto® improves productivity in printing and packaging operations

Optimize your printing and packaging production with Cellasto®. This high-performance, microcellular polyurethane foam is engineered for resilience and durability to increase accuracy and reduce costly downtime of your printing, cutting and paper-handling equipment.

Why innovators choose Cellasto® for paper and packaging operations

BASF is your experienced partner in engineering designs that meet your specifications while increasing accuracy and performance. The versatility of Cellasto® enables innovators to craft custom designs to meet the unique demands of their customers.

Die cutting

Apply this resilient elastomer to obtain firmer, more secure positioning of your packaging and paper material, ensuring greater accuracy during the cutting process. Count on the high-speed recoil of Cellasto® to consistently eject die-cut material and its extremely high durability to keep your equipment running smoother for longer. Because it’s readily available, you can achieve high performance both rapidly and economically.

Flexo printing

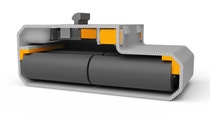

Incorporate Cellasto® in the design of your flexo plate cylinders to improve the quality and output of your printing process. The material’s high compressibility and quick rebound will improve the ease of roller mounting on base layers. In sleeves, the elastomer’s resilience will rapidly restore roll form, providing consistent and even pressure at high speeds. Not only that, but its superior durability will extend equipment run time.

Paper handling and folding

Improve the consistency and durability of your paper handling and folding processes with Cellasto®. With unique compressibility, it provides more grip and smoother control than conventional materials. And with superior abrasion resistance, Cellasto® ensures high performance over greater durations.

Cellasto® ensures cost-effective, accurate paper and packaging operations

In printing and packaging, where maximizing run time and optimizing accuracy are essential, Cellasto® offers distinct characteristics that meet your needs economically while ensuring high-quality performance.

Advantages of Cellasto® components

- High-volume compressibility with minimal lateral expansion

- Outstanding low compression set

- High abrasion resistance

- High chemical resistance

Leverage the versatility of Cellasto® to make your innovations a reality.

BASF: Your global partner in paper handling and packaging solutions

Count on BASF as your partner for:

- Efficient, worldwide supply chain to maximize value

- Global connections to shorten acquisition time

- Development, simulation and testing to help you refine your design

- New technologies give you a market advantage

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.