Plastics & Rubber

News

For media inquiries and press related questions, please contact one of our communicators in your region.

News

At Plastindia 2026, BASF showcases how light stabilizers extend the durability of plastics across industries

Boosting solar resilience through Xfloat and BASF collaboration

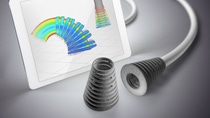

BASF continues its VALERAS® journey with new additive solutions at K 2025

Takazuri and BASF collaborate to support climate resilient construction in Eastern Africa

BASF launches game-changing heat and light stabilizer Tinuvin® NOR® 211 AR for sustainable farming practices

BASF accelerates its Plastics Journey at Plastics Recycling Show Europe 2024

This News Release is only available in English

Joint News Release - Chemovator invests in Detroit-based startup Heartland rethinking plastics using natural fiber reinforcements

BASF to showcase sustainable additive solutions at CHINAPLAS 2024

BASF joins CHINAPLAS 2024, a landmark event in the plastic and rubber industries, to present its latest additive offerings, which significantly increase the sustainability of various plastic applications. These solutions help customers from the plastics industry achieve their sustainability goals by improving durability, reducing emissions, and enhancing the performance and quality of recycled plastics.

This News Release is only available in English

BASF launches Irgastab® PUR 71, a cutting-edge antioxidant improving regulatory compliance and performance for polyols and polyurethane foams

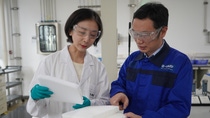

BASF and Teamplas give waste a second life

BASF and Teamplas Group, a leading manufacturer of recycled pellets in Southeast Asia, have collaborated to transform post-consumer waste into new high-quality office equipment and car interior parts with the help of BASF’s IrgaCycle®.

This News Release is only available in English

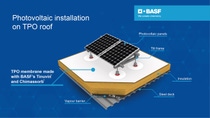

BASF partners with Oriental Yuhong for solar rooftop solutions in China

BASF and Oriental Yuhong, a leading Thermoplastic Polyolefin (TPO) roofing membrane producer in China, are teaming up to develop solar roofing membranes used in buildings. The new development aims to meet China’s rapidly growing demand for rooftop solar panels.

This News Release is only available in English

BASF launches first biomass balance plastic additives

BASF continues its Plastics Journey at Plastics Recycling Show Europe 2023

BASF gains ISCC PLUS certification to expand its VALERAS® offerings for plastic additives

BASF and Noria Energy install first of its kind floating solar system at BASF’s manufacturing site in the United States

As part of its sustainability goal of achieving net zero CO2 emissions1 by 2050, BASF has installed an innovative proof-of-concept floating solar system at its McIntosh, Alabama manufacturing site. Noria Energy’s first of its kind floating solar system uses renewable energy to power three aerators used to improve the water quality of a scenic pond at the production facility.

This Press Release is only in english available

Achim Sties appointed new Senior Vice President of BASF plastic additives

BASF offers neopentyl glycol and propionic acid with product carbon footprint of zero

BASF to debut VALERAS™ for its plastic additives portfolio at K 2022

BASF offers product carbon footprints to its plastic additives customers through myPlasticAdditives

BASF’s IrgaCycle™ stabilizes recycled plastics used to protect pineapples from sunburn in Malaysia

Joint News Release - BASF and THOR GmbH fight fire together

Joint News Release - Confoil and BASF cooperate to develop certified compostable dual ovenable paper tray for packaging of ready-to-eat meals

BASF at K 2022: Accelerating the journey towards a sustainable future with plastics

“At K 2022, our theme is ‘Go!Create – Welcome to Our Plastics Journey’,” says Dr. Martin Jung, President Performance Materials, “We invite all visitors to join our journey towards a sustainable future with plastics. We will show products and solutions and more than that we want to give insights in our concepts and plans. The Plastics Journey towards a more sustainable economy needs a co-operative approach and has a long way to go. That’s what we want to express.” The Plastics Journey consists of three phases which represent the lifecycle of plastics: MAKE, USE, and RECYCLE. BASF offers market-leading products and solutions for all three phases of this journey.

BASF offers range of chemical intermediates with product carbon footprint significantly below global market average

BASF light stabilizer increases the durability of pontoons used for aquaculture in China

BASF highlights progress in enabling plastics circularity at Plastics Recycling Show Europe 2022

BASF doubles its production capacity for Irganox® 1010 in Singapore

BASF launches Ultradur® B4335G3 HR HSP – all-rounder for reliable protection

Busbar holders made of Elastollan® R 2600 FHF – More safety for future mobility

BASF and REEF Technology sign strategic cooperation agreement to improve the quality of plastic recyclate materials

Extremely safely packed in ex zones

BASF launches RegXcellence® for plastic additives, a new service for Regulatory Excellence

Small and incredibly fast – new connector system with Ultradur®

Fakuma 2021 – BASF opens up endless possibilities with a variety of sustainable plastics solutions

BASF introduces IrgaCycle™, new additive solutions for mechanical recycling of plastics

Lightweight and emission reduction – roof frames made with Ultradur® High Speed

BASF, L&L Products and Stellantis collaborate for lightweight success on the 2021 Jeep Grand Cherokee L

BASF’s Irgastab® enables LOTTE Chemical to deliver high-clarity medical polypropylene for syringes used in COVID-19 vaccinations

The new star among the standards – the heat-stabilized Ultramid®

BASF opens its own virtual platform for Fakuma 2020