Rubber Additives

Koresin®

High Performance Tackifier for the Rubber Industry

Part of BASF's rubber chemicals portfolio is the tackifier Koresin®. It is the industry benchmark with regard to superior tack performance, processing flexibility, reliability, high quality and uniformity.

Koresin® is successfully applied in the manufacturing of quality and premium tires in OEM, replacement and re-treading as well as industrial and technical rubber goods.

Our customers benefit from our expertise with Koresin® which extends back more than 80 years. They also benefit from the outstanding advantages of Koresin®: It provides high initial and long-term tackiness to rubber compounds and it is compatible with all current rubber formulations. Koresin® allows adjustment of tackiness according to the processing needs, thus delivering reliable tack at all desired levels.

Koresin® is available worldwide through BASF or its partners.

Koresin® is now available in two variants for advanced sustainability

Koresin® Ccycled®

- Using recycled feedstock from plastic waste

- 100% substitution of fossil with sustainably certified recycled feedstock in the value chain

- Contribution to saving of finite fossil resources

- Drop-in solution: identical quality and properites compared to standard Koresin®

- Manufactured in a certified mass balance approach

Koresin® BMBcert™

- Using renewable feedstock

- 100% substitution of fossil with renewable raw materials in the value chain

- Contribution to saving CO2 emissions

- Drop-in solution: identical quality and properties compared to standard Koresin®

- Manufactured in a certified mass balance approach

Find further information

Koresin® is successfully applied

in the manufacturing of

quality and premium tires of all kind

- for cars, trucks and special vehicles

- for OEM, replacement and re-treading

- in light, medium, heavy and speed use operations

- in earth and air transport rubber compounds

other industrial and technical rubber goods, such as

- conveyor belts

- power transmission belts

- hoses

- cable / roll coverings

- lining materials

Outstanding Advantages

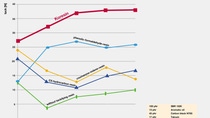

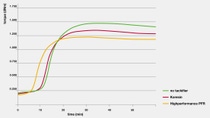

- High initial and long-term tackiness of rubber compounds

- Compatible with all current rubber formulations

- Processing flexibility

- degree of tackiness can be adjusted

- tackiness can be maintained for up to several weeks

when needed - Koresin has no negative influence on the

- vulcanization kinetics

- properties of the vulcanized rubber - Proven effectiveness also in formulations with high loading of silica filler