- 20%

reduced buffer diameter at same load range

Cellasto® - where creativity meets performance

Automotive

Meet today’s standards for elevator comfort with Cellasto®. This high-performance microcellular polyurethane elastomer reduces noise, vibration and harshness (NVH) ensuring your elevators offer passengers a smooth, quiet ride.

BASF is your experienced partner in the elevator industry, providing custom-designed and safety-certified components crafted with the outstanding versatility of Cellasto®. Count on BASF’s team of global experts to help you engineer designs that meet your specifications for NVH, safety and performance.

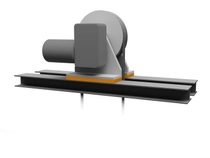

Elevator overrun buffer

Thanks to advanced formulations of Cellasto® HD, your elevator overrun buffers will have the significantly improved ability to absorb energy. Maintain the same load range with a smaller buffer diameter or gain wider load range with keeping the diameter. Request a customized Cellasto® solution for country-specific standards.

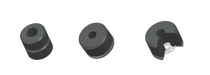

Engine bearing

Control noise and vibration NVH produced by the elevator’s engine with Cellasto®. Cellasto offers outstanding vibration isolation and long-term durability.

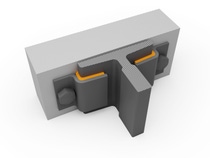

Cabin isolator

Reduces the vibration of the pulley beams by decoupling the passenger cabin from the elevator’s hoisting mechanisms.

Rail isolator

Avoid the transmission of operational vibration into the building structure with Cellasto® rail isolators. Design a custom solution to fit your guide rail fixing method.

Rope buffer

Control acceleration peaks with Cellasto® rope buffers at cabin and counterweight during starting and stopping movements.

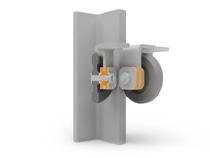

Roller guide mounts

Keep wheels in position and isolate the elevator’s passenger cabin from noticeable wheel vibration. Reduce cost and weight by a simple, customized Cellasto® solution.

- 20%

reduced buffer diameter at same load range

+ 40%

increased load range at same buffer size

| Cellasto HD Lift Buffer | Load range at nominal speed up to 1 m/s |

Load range at nominal speed up to 0,63 m/s |

EU Type Examination | ||||

| Buffer Typ |

Dimensions [D x H] |

BASF Prod.-Nr. |

min Load [kg] |

max Load [kg] |

min Load [kg] |

max Load [kg] |

Certificate Registered No. |

| 80x80 - A | Ø 80 x 80 mm | 45 2298 27 | 180 | 700 | 140 | 1650 | 44 208 120 827 24 |

| 80x80 - B | Ø 80 x 80 mm | 45 2298 48 | 350 | 1400 | 250 | 3000 | 44 208 120 827 25 |

| 100x80 | Ø 100 x 80 mm | 45 2298 49 | 450 | 1700 | 330 | 3900 | 44 208 120 827 26 |

| 125x80 | Ø 125 x 80 mm | 45 2298 50 | 600 | 2000 | 350 | 4800 | 44 208 120 827 27 |

| 140x80 | Ø 140 x 80 mm | 45 2339 79 | 450 | 1500 | 300 | 4500 | 44 208 120 827 31 |

| 165x80 | Ø 165 x 80 mm | 45 2298 52 | 950 | 3600 | 700 | 9400 | 44 208 120 827 28 |

| 140x110 | Ø 140 x 110 mm | 45 2298 51 | 500 | 3200 | 400 | 6000 | 44 208 120 827 29 |

| 220x80 | Ø 220 x 80 mm | 45 2339 80 | 1500 | 5600 | 1000 | 9400 | 44 208 120 827 30 |

Your Cellasto® elevator components will meet today’s expectations of smooth, quiet motion that communicates high-quality performance. With custom solutions co-created with BASF’s team of experts, your innovations will know no limits.

In elevator components where dynamic forces are at work, Cellasto® decouples the critical contact points. Even in small spaces, Cellasto® ensures excellent acoustic and vibration damping. Isolate the passenger cabin and building effectively with Cellasto® as your most versatile solution to reduce NVH.

Cellasto® components offer the following advantages:

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.