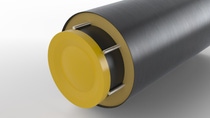

- Infill density: 100 – 250 kg/m3

- Impact test: > 12 KJ

- Open-cell content: > 80 %

- Water uptake: neutral buoyancy

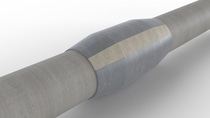

Construction

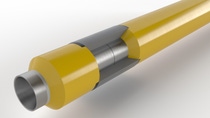

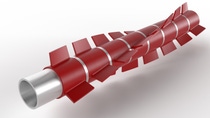

Polyurethane products for the oil and gas industry: superb solutions for subsea conditions.

Construction products and materials for infrastructure pave the way for efficient and sustainable design in- and outdoors. We offer a large range of products for different applications tailored to your needs. With our polyurethanes, special foams, engineering plastics and additives, we contribute to a sustainable future.

Maximum performance on- and offshore requires thinking big right down to the smallest detail – that is our speciality! Product features and techniques for on- and offshore and subsea applications could not be more sophisticated. Resulting from decades of experience, BASF knows the oil and gas industry’s key factors for success – and offers state-of-the-art solutions for all systems and challenges.

Applications

Tailor-made Solutions

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

Consult with an expert

Self-service solutions: