Elastocoast®的主要优势

- 使得海岸更加安全

- 多孔性和透水性

- 吸收冲击波的能量

- 对环境无害

- 坚固和持久

高性能聚合物

Elastocoast®是一种新型的、智能的聚氨酯系统。它是一种双组分粘合剂,用于沿海地区的护岸和河岸的稳定。它是如此的开放,以至于它消除了波浪上升的破坏性能量,显示了它的强度,使海岸和河床更加安全。Elastocoast®也被证明可以作为水下防波堤,是海洋植物恢复的理想选择。

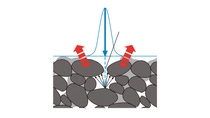

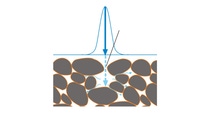

由Elastocoast®制成的护岸是一种新的、极其有效的海岸保护系统。它们由骨料(碎石)与环境兼容的双组分聚氨酯塑料机械地粘合在一起组成。这种混合物被应用于准备好的堤坝、墙壁、防波堤和其他海洋和淡水海岸线。其结果是一个非常耐用、坚固,因而安全的堡垒,可以抵御海浪和高水位。这是通过将波浪能量分布在更大的区域,减少表面压力的局部集中而实现的。在护岸上的压力更小。与完全反映波浪破坏力的密封表面相比,多孔表面通过孔隙体积的摩擦吸收部分水能,并最终将其转化为热能。因此,水体以较少的水力能量实现较低的波浪上升,从而减少了破坏的可能性。

传统的混凝土护岸的受力情况

Elastocoast®护栏有效地吸收了波浪能量

Elastocoast®使现有的堤坝更加安全,而不需要不断地提高它们,由于经济成本和实际原因,如缺乏空间,这是很难做到的。在这里,一个开孔和吸能的顶层可以防止海浪的冲击能量攻击和破坏表面,创造一个更高的安全标准。Elastocoast®也可用于修复旧的、完全倾覆的堤坝,使其更加安全。通常情况下,堤坝倾覆是一种危险的情况,因为随后陆地一侧的侵蚀不可避免地会导致堤坝完全崩溃。然而,Elastocoast®可以直接应用于现有的护堤--不需要大量的预处理,也大大减少了劳动力。

通常情况下,防波堤是作为一个混凝土四合院来建造的。然而,混凝土的毒性和它的强碱性造成了问题。此外,需要一个大的堆场,和一个长的生产时间(>10天),并产生严重的灰尘(水泥和沙子)。Elastocoast®对环境是中性的。它减少了冲刷和侵蚀,由于其高孔隙率,导致水的速度较低。因此,Elastocoast®是浸没式防波堤的理想选择。

Elastocoast®砌块

Elastocoast® 砌块被放进水中

渔业和旅游业导致了海洋的荒漠化,从而导致海洋植物和鱼类的缺乏。在过去,人们使用混凝土制成的人工鱼礁,但它们没有立即的效果。Elastocoast®为海洋植物的恢复提供了一个优异的环境。将Elastocoast®块放置在海床上,一年后就能恢复植物生命。此外,观察表明,它导致了鱼类和海洋动物的回归。在观察中,30毫米的石头被证明是最适合吸引生命的。

在海岸保护方面已经被证明是成功的,也可以用于河岸和运河。这里的目标也是创造一个强大的和接近自然的护岸,以巩固海岸区,并稳定它们,以防止交通引起的波浪和潮汐。在水路工程中,也有可能进行水下安装,在充分的反应时间后,将岩石-聚氨酯混合物倒入靠近岸边的水中并压实。其原理与堤坝建设一样简单,可以保护堤岸不被强流瓦解和破坏。

所用的石头在加工前必须是干净的,表面干燥的。这是一个乍看之下很困难的要求。正如其他已实现的项目所示,这一障碍可以通过处理和物流方面的简单措施来克服。Elastocoast®由大约50%的植物脂肪酸酯组成,因此是可再生的原材料。此外,由于空隙率高,它为动物和植物提供了额外的栖息地。Elastocoast®表面层也能和谐地融入景观。由于材料的透明性,它们与自然界的彩色面层几乎没有区别。在材料完全固化之前,表面应覆盖干燥的沙子,这可以进一步改善视觉效果,并创造一个防滑的表面。

植物和动物的优异基质

阿姆斯特丹大学的生物研究表明,使用Elastocoast®的护岸在几周内就会被该地典型的动植物群落吸收。与传统的、不透水的海岸保护结构不同,Elastocoast®护栏的空洞也为动植物提供了额外的栖息地。

生态效率分析说明了一切

为了证明新的Elastocoast®技术的环境影响和生态效益,进行了全面的生态效率分析。这涉及到对各种产品和工艺在整个生命周期中的环境影响进行分析。生命周期评估以DIN EN ISO 14040和14044为基础,并由柏林TÜV认证为一种整体方法。Elastocoast®与传统的海岸保护方法如混凝土和开石沥青(OSA)进行了比较,面积为20,000平方米。

盖尔森基兴的环境卫生和毒理学研究所的研究证实了PU系统在海岸保护中的毒理学和环境医学安全性。对稳定性、抗侵蚀性、重新安置、抗风化和抗盐水以及许多其他参数的长期观察和检查表明,Elastocoast®护岸已经在关键点上达到了最高值。

耐候性

水利工程结构应该有20年以上的使用寿命。所有基于无机(水泥结合)或有机(塑料)的建筑材料在户外使用时都会受到天气的影响。应特别注意由紫外线辐射、盐水和霜冻造成的损害。PU材料已经在户外应用中证明了自己,如混凝土和运动场或海上、石油和天然气管道的涂层,以防止盐水的影响。在海水中发生的降解过程已经通过逐渐增加温度到80°C来加速。通过这种方式,结果可以推断到20-30℃。这种推断表明,聚氨酯材料在20-30℃的工作温度下,在盐水或海水中是完全稳定的,并且有80-100年的使用寿命。TUHH提供的证据表明,对紫外线照射有足够的抵抗力,这一点已经在专门设计的水过渡设施中进行了测试。根据DIN EN 13383-2的测试,抗冻性得到了保证。

自助方案: