Performance Polymers

Cellasto® improves NVH for superior safety and performance of light vehicles

Give your light vehicles a competitive edge with Cellasto®. This high-performance microcellular polyurethane elastomer reduces noise, vibration and harshness (NVH), ensuring your electric and all-terrain vehicles operate safely and last longer.

Why innovators choose Cellasto® for light vehicles

BASF is your experienced partner in light vehicle manufacturing, providing custom-designed and safety-certified components crafted with the outstanding versatility of Cellasto®. Count on BASF’s team of global experts to help you engineer designs that meet your specifications for NVH, safety and performance.

UTV’s (side-by-side) and ATV’s (Quad, 4-wheeler)

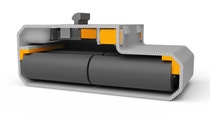

Add Cellasto® to suspension components to give your all-terrain and utility vehicles a smoother and safer ride. The high compressibility of Cellasto® boosts the performance of your jounce bumpers without compromising their durability and can be applied in small installation spaces. Even in grimy conditions, Cellasto® sustains its outstanding capabilities and extends the life of your products.

Motorcycles

Improve your on-road and off-road motorcycle’s performance and durability using Cellasto®. High compressibility, along with oil, fuel and grease resistance, makes it ideal for use in motorcycle jounce bumpers and drive dampening components. This unique material’s low stiffness while under compression across a broad range of vibrational frequencies makes it ideal for motorcycle NVH reduction.

Snowmobile

Incorporate Cellasto® into your snowmobile’s design to give your riders a significantly smoother experience. Cellasto® offers responsive dampening for both high and low impact, improving your snowmobile’s suspension dynamics. In icy temperatures and gritty conditions, Cellasto® also maintains its high performance, enhancing steering capabilities, improving seat suspension, and reducing vibration transmission.

Electric vehicles, golf carts

Upgrade the comfort and safety of your products when you add Cellasto® to components for electric vehicles, scooters, and golf carts. Through its high resilience, Cellasto® provides superior vibration reduction of powertrains and better impact protection for motors and battery packs.

Cellasto® ensures safe, durable light vehicle performance

Designing with Cellasto® will give your light vehicles a competitive edge by extending product life, reducing NVH, and improving rider protection. In suspension components, Cellasto® outperforms other elastomers.

High resilience, compressibility, and wear resistance under demanding conditions make it the solution of choice for producing long lasting, dependable components for light vehicle applications. Custom solutions co-created with BASF’s team of experts make the possibilities for your innovations limitless.

Advantages of Cellasto® components

- Progressive load deflection curve provides a soft start and high load capabilities

- Superior energy absorption

- Unusually high compressibility

- Cold, heat and dirt resistant

- Excellent static and dynamic long-run behavior

- Low dynamic stiffening and amplitude-selective dampening

- High-abrasion resistance

- Resistance to oil, fuel, grease, ozone, and other substances

BASF: Your global partner in light vehicle manufacturing

The Cellasto® team helps you keep pace with the high expectations of your customers. Count on BASF as your partner for:

- Development, simulation and testing to help you refine your design

- Global reach that shortens your acquisition time

- New technologies you can leverage for market advantages

- Efficient, worldwide supply chain management that ensures maximum value

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.