Construction

Paving the way – materials for infrastructure

Construction products and materials for infrastructure pave the way for efficient and sustainable design in- and outdoors. We offer a large range of products for different applications tailored to your needs. With our polyurethanes, special foams, engineering plastics and additives, we contribute to a sustainable future.

Good infrastructure – for humankind and the environment

To create a modern and inviting living environment, we need materials and product ideas that are functional, sustainable and attractive at the same time. Our materials deliver not just one-off solutions, but many possible applications ranging from coastal protection and surface design for pathways, roads and car parks through to pipeline insulation, road and rail track construction and the protection of artificial ice rinks.

If you want to go new ways, the innovative Elastopave® system is the perfect choice for the design of paths, plazas, surfaces and even garden objects. Open-pore, stable and water-permeable - it offers completely new possibilities for surface applications in all areas. Stable and more environmentally compatible than conventional solutions, this material comprises integrated water management and optical flexibility.

Let yourself be inspired by the incredible potential of this new product idea from BASF.

Coastal protection also calls for more than forward-ideas application of intelligent concepts. The polyurethane system Elastocoast® makes not only our coasts safer, but also river banks, river beds and landslide-threatened slopes. Elastocoast® is a permeable coating of covering layers in coastal areas. The open-pore structure reduces the destructive force of high tides right from the start. It stands up even to the strongest waves.

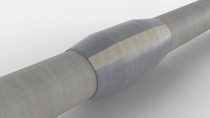

With highly advanced pipeline coatings, we improve safety, offshore and onshore. Pipelines need one thing above all: Absolutely reliable protection, well above standard. For years, BASF has been offering a multitude of highly sophisticated detail solutions that have proven themselves in extremely heavy-duty conditions. Because they work – simply, trouble-free and reliably every time. The performance spectrum of the state-of-the-art polyurethane systems Elastopor® and Elastoshore® that BASF are now able to offer the industrial sector comprises flexibility, durability, loadability, heat insulation and impact resistance.

More safety – less wear and tear.

How BASF materials further optimise applications for the oil & gas industry

Maximum performance on-and offshore requires thinking big right down to the smallest detail – that’s our speciality! Product features and techniques for on- and offshore and subsea applications couldn’t be more sophisticated. Resulting from decades of experience, BASF knows the oil & gas industry’s key factors for success – and offers state-of-the-art polyurethane solutions for the oil & gas industry. Solutions for all systems and challenges.

Polyurethane and steel – a connection with a future

SPS® - Sandwich Plate System – is a structural composite used in the civil, maritime and offshore sectors. BASF developed SPS with the British company, SPS Technology, over 20 years ago. It is approved by major regulatory authorities in a wide variety of civil, offshore, maritime and special applications including: stadium terraces, structural flooring, bridge decks, offshore structures and maritime vessels.

SPS comprises two metal plates bonded by Elastocore® (polyurethane). The core provides global support to the faceplates, eliminating weak spots or local buckling.

SPS - for civil engineering, bridges and buildings

In the civil market, this structural composite replaces reinforced concrete used in stadium risers, floors and bridge decks. Considerable weight savings lead to reduced foundations and supporting structure and pre-fabrication allows faster and safer construction with reduced schedules and risk.

SPS is used for the repair and upgrade of vessels, offshore structures and bridge decks where the original structure is used as one side of the new composite sandwich. In the maritime and offshore markets where SPS is used for components instead of conventionally stiffened steel, vital space is saved with simplified structure which are easier to inspect and maintain.

SPS, with its Elastocore® polyurethane filling, delivers a number of benefits over conventional construction materials including impact-resistance, vibration and acoustic damping, blast, ballistics and fire protection and thermal insulation.

20 years of delivering SPS structural composites

With a world-wide network of partners, SPS is recognised and delivered in all sectors internationally. The technology has become a recognized and proven process worldwide. SPS Technology looks to build new markets for SPS, provides technical advice, secures materials approvals, develops new products and continually advances SPS technology.

Plastic Solutions for Infrastructure

Tailor-made Solutions

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

Consult with an expert

Self-service solutions:

![Verlegung der Gas-Pipeline für die Plattform A6-A. Pipeline-Verlegeschiff SOLITAIRE.

Hier: Die Schweißer der Root-Station steuern ihre Schweißautomaten per Knopfdruck. Ganz nah beugen sie sich über den Lichtbogen, um die Qualität der Naht genau zu kontrollieren.

[ (c) Klaus Andrews, Carlshöhe 21, D-24340 Eckernförde, Germany, Tel. +49-4351-88 99 665, Mobil +49 (0)171 - 413 31 20, www.KlausAndrews.com, mail@KlausAndrews.com, Konto-Nr. 1268491444, BLZ 200 505 50, HASPA. IBAN: DE59 2005 0550 1268 4914 44 BIC HASPDEHHXX, www.freelens.com/clearing, Jegliche Verwendung nur gegen Honorar, Urhebervermerk und Beleg; Bei Verwendung des Fotos ausserhalb journalistischer Zwecke bitte Ruecksprache mit dem Fotografen halten. No modelrelease! ][#0,121#] Verlegung der Gas-Pipeline für die Plattform A6-A. Pipeline-Verlegeschiff SOLITAIRE.

Hier: Die Schweißer der Root-Station steuern ihre Schweißautomaten per Knopfdruck. Ganz nah beugen sie sich über den Lichtbogen, um die Qualität der Naht genau zu kontrollieren.

[ (c) Klaus Andrews, Carlshöhe 21, D-24340 Eckernförde, Germany, Tel. +49-4351-88 99 665, Mobil +49 (0)171 - 413 31 20, www.KlausAndrews.com, mail@KlausAndrews.com, Konto-Nr. 1268491444, BLZ 200 505 50, HASPA. IBAN: DE59 2005 0550 1268 4914 44 BIC HASPDEHHXX, www.freelens.com/clearing, Jegliche Verwendung nur gegen Honorar, Urhebervermerk und Beleg; Bei Verwendung des Fotos ausserhalb journalistischer Zwecke bitte Ruecksprache mit dem Fotografen halten. No modelrelease! ][#0,121#]](/api/imaging/focalarea/16x9/210x/dam/jcr%3A6d6062d4-9215-3118-bfec-109e77f23b2a/construction_infrastructure_welding_pipeline.jpg)