Plastics for Furniture

Where furniture designers come to be inspired -

BASF materials for innovative and sustainable furniture

At BASF, we want to help make your sustainable innovation journey faster when it comes to furniture design. We have expanded our portfolio to include innovative materials that support sustainable goals — while still giving furniture designers creative inspirations.

Sustainable furniture solutions made with

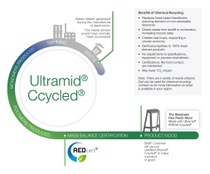

The Ultramid® Ccycled® process

works for the Steelcase Flex Perch Stool

The Steelcase Flex Perch Stool.

Made with Ultramid® B3EG6 Ccycled®

Ultramid® B3EG6 Ccycled® is an injection moldable polyamide (Nylon) 6 material that is made from a diverted waste stream generated during electronics production. The waste stream would have been incinerated but instead was used to create a high value, durable product. Learn more about the Steelcase Flex Perch Stool including how to purchase here.

- High strength and stiffness

- Excellent surface finish

- Same performance as virgin/fossil based material

- Supports a circular economy by creating a new life from a waste stream

- Available in standard black, and uncolored, as well as custom pre-colored

The BASF’s Mass Balance Approach

In the chemical industry, renewable or recycled raw materials are added at the beginning of the production process and added to the final product. This offers several advantages: It reduces both greenhouse gas emissions and the use of fossil raw materials, while the quality and properties of a product remain the same. Thus, the products can be processed in the same way as conventionally produced materials. So no formulations, equipment or processes need to be adapted. And customers who buy mass-balanced products can use them like conventional products and benefit from the same quality.

Learn more

Boln seat

with Elastoflex® W BMB

Elastoflex® W is the brand of the flexible polyurethane foams. The structure of the foam provides the required resistance to hold the body and provide the right comfort in each application. Properties like density, fire resistance and compression can be adapted to the market needs. These excellent properties remain unchangeable when the BMB approach is used, but in addition a considerable reduction of the PCF is obtained. No need to compromise performance for being sustainable.

- High elasticity

- Good flowability for the production of complex geometries

- Excellent long-term characteristics

- Open-celled

- Pleasant feel

Sustainable furniture solutions

That spark design creativity

Sustainable Office Furniture

with Nypel® 6253G

Made from post-industrial materials, Nypel 6253G will help you achieve your sustainability goals. Whether you’re designing chair backs, bases or seat frames, you can benefit from Nypel’s high strength and toughness. Discover the design freedom of a wide range of pigmenting options with the uncolored version. Be prepared to get inspired!

Ultramid® B3EG6 Ccycled™ for chair frames

- High strength and stiffness

- Excellent surface finish

- Available in standard black and uncolored as well as custom pre-colored

Elastollan® TPU over Elastoflex® PU foam for arm rests

- Comfortable surface with soft feel

- High wear

- Colorable

OR Waterblown Integral Skin Foam for arm rests

- One shot core and skin

- High comfort

- Great wear

- Colorable

Elastoflex® polyurethane foams for seat cushions

- Excellent resiliency and comfort

- Low VOC

- Wide range of densities and firmness

- High resiliency and visco-elastic formulations available

Nypel® 6235 for chair bases

- Good physical properties and flow

- Available in standard black and uncolored

Ultramid® B3EG6 Ccycled™ for chair arms

- High strength and stiffness

- Excellent surface finish

- Available in standard black and uncolored, as well as custom pre-colored

Elastoflex® polyurethane foams for seat cushions

- Excellent resiliency and comfort

- Low VOC

- Wide range of densities and firmness

- High resiliency and visco-elastic formulations available

Nypel® 6235 for chair bases

- Good physical properties and flow

- Available in standard black and uncolored

Elastollan® TPU for chair wheels

Haptex® non-solvent polyurethane leather for seat & back covers

- First solution for synthetic leather with zero organic solvents

- Wide range of textures, patterns and colors

Haptex® non-solvent polyurethane leather for seat & back covers

- First solution for synthetic leather with zero organic solvents

- Wide range of textures, patterns and colors

Watch our talk with the danish furniture manufacturer Bramming Plast-Industri A/S here:

Consult with an expert

Self-service solutions: