Performance Polymers

Infinergy®(E-TPU) is Empowering Movement

We are accelerating with the world's first expanded thermoplastic polyurethane (E-TPU). With Infinergy®, we help game changers and go-getters move ahead in life. We empower workers to move like athletes, children to play more safely and athletes to perform at their best.

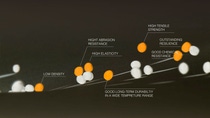

Infinergy® provides superior energy return while delivering a lightweight, high strength alternative. Infinergy® adds next-level comfort and flexibility in a variety of applications ranging from footwear to flooring to sports equipment.

How can Infinergy® benefit you?

Infinergy® Revolution: Efficient processing of high-performance soles

Infinergy® transformed the footwear industry ten years ago. Now Infinergy® Revolution provides access to a variety of molding processes while keeping the Infinergy® identity of making shoes very comfortable to wear and delivering excellent running properties. Due to new processing methods the material can be fused into soles in a much more energy-efficient and material-friendly manner. With endless design possibilities many surface textures are available. Its durability and recyclability allow Infinergy® Revolution to strive for a more sustainable future of the footwear industry.

News

Tailor-made Solutions

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

Consult with an expert

Self-service solutions: