Ultradur® can be processed by all methods known for thermoplastics. The main methods, however, are injection molding and extrusion. The extrusion process is used to produce profiles, pipes, mandrels and semi-finished products. Semi-finished products are for the most part machined further by means of cutting tools to form finished moldings.

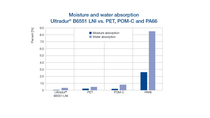

By connecting and branching of the polymer chains via tailor-made additives the experts of BASF gained a very high melt strength which makes the Ultradur® B6551 LNI for extrusion the perfect material for pipes, profiles and mandrels. Ultradur® B6560 M2 FC TF is the only PBT solution for extrusion of films and thermoforming for appliances in packaging or technical parts. The excellent processability was confirmed by our innovative partner ILLIG, one of the biggest producers of thermoforming machines.

More details on Ultradur® extrusion processing