Innovators know Cellasto® is the best choice to achieve NVH reduction. In fact

85%

of today's car manufacturers currently use Cellasto® components.

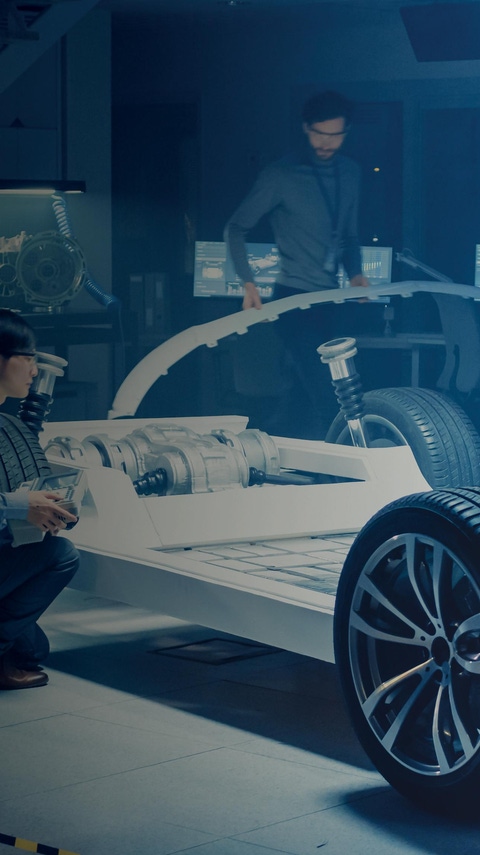

Cellasto® - where creativity meets performance

Automotive

Discover new market-ready solutions with Cellasto® components that deliver superior noise, vibration and harshness (NVH) reduction. Engineered for OEMs and tier suppliers worldwide, Cellasto® parts will meet your unique specifications. No design challenge is too great for the team of Cellasto® experts. Your innovations will come to life, and your products will offer smooth, quiet performance that promises high quality.

Noise, vibration and harshness are features of the practical performance of many automotive, industrial and consumer products. NVH translates into how the end-user experiences your product and judges its quality. They know it when they see it, hear it and feel it. Cellasto® reduces NVH effects to help you create value—including quieter experiences and smooth handling for your customers.

For nearly 60 years, innovators worldwide have chosen Cellasto® again and again to meet the ever-advancing pace of technology in industries such as automotive, elevators, home appliances, powertools, heavy equipment, sports and gaming, just to name a few. They rely not only on the extremely versatile material properties of Cellasto®, but also on the know-how and co-creation capabilities of BASF’s engineering team.

Innovators know Cellasto® is the best choice to achieve NVH reduction. In fact

85%

of today's car manufacturers currently use Cellasto® components.

With BASF’s material selection expertise, you’ll be able to align Cellasto® to your custom specifications.

BASF will test your product and help you overcome complex challenges with our technical support and state-of-the-art testing facilities. Discover new joining technologies for multi-material applications that offer light weight and exceptional performance.

BASF and the Cellasto® team support your innovations from conception to serial production. Count on BASF as your partner for:

Guaratingueta in Brazil

Manufacturing site

Start of production in 2013 and the Cellasto production in Brasil started in 1984

Lemförde in Germany

Manufacturing site and regional technical center

Start of production in 1961

Wyandotte, MI in North America

Manufacturing site and regional technical center

Start of production in 1986

Shanghai in China

Manufacturing site and regional technical center

Start of production in 2010

Dahej in India

Manufacturing site

Start of production in 2014

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.