Performance Polymers

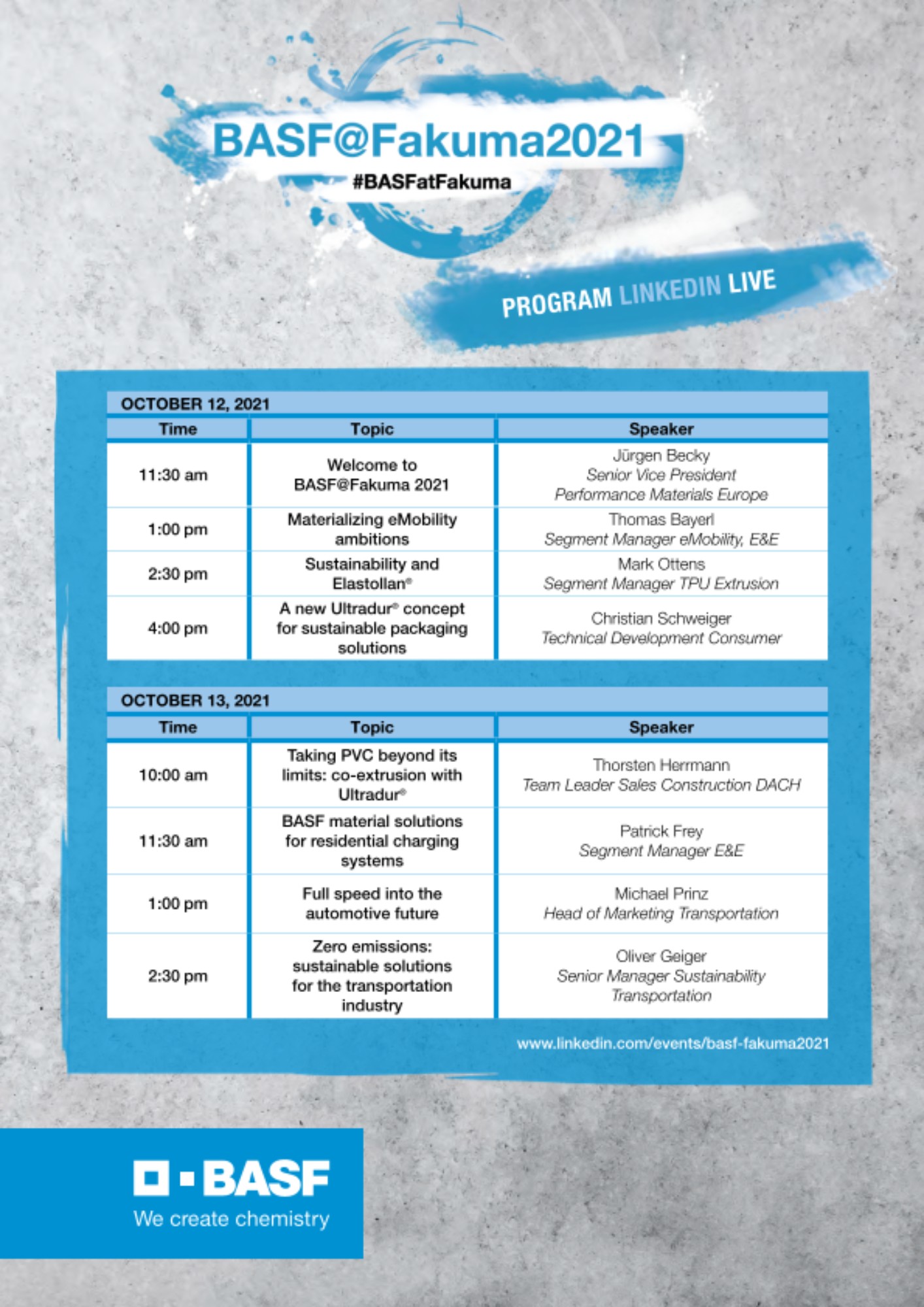

BASF@Fakuma 2021

Not only the digitalization is gaining in importance but also sustainability. Plastics are an essential part of our modern lives. At the same time, they have become one of the most discussed topics worldwide.

At Fakuma we invite you to discuss with us new innovations in the plastic industry from October 12-16. After the fair you can book an appointment with our experts – virtually.

This year's topics at Fakuma

The public is thinking more than ever about how plastics are used and why. Together with customers and partners, BASF has set itself the goal of a circular economy in which raw materials are conserved, plastic waste is reduced to a minimum and materials can develop their full potential during use.

Meet the expert from October 18 - 29, 2021 !

After the fair you have the opportunity to discuss with our experts about your favorite topics surrounding transportation, sustainability, appliances and many more! Are you interested? Book your meeting here!

Andreas Wollny

Digitalization

Oliver Geiger

Sustainability Automotive

René Holschuh

Automotive Powertrain

Thomas Bayerl

eMobility/ E&E

Thomas Mathieu

PU Automotive

Mark Staniford

PU Automotive

Patrick Frey

E&E/ eMobility/ Automotive Engineering Plastics

Kay Brockmüller

Construction – Ultradur Co-extrusion

Tatiana Ulanova

Packaging/ Extrusion Engineering Plastics

Mark Ottens

Thermoplastic Polyurethane

Sebastian Wagner

Sustainability Appliance and Powertools

Albert Camp

Consumer Furniture and Packaging

Maximilian Lehenmeier

Product Development Engineering Plastics

Sebastian Allinger

Technical Development – Appliance, Powertools, Sport, Leisure

Carsten Junghans

Global Business Development Ultrason

Kai Beringer

Simulation Expert: Nonreactive Process Simulation (Moldflow)

Jochen Schmid

Ultrason® Water, E/E, Healthcare

Georg Grässel

Ultrason® Household, Bottles

Thomas Hohenstein

Structural Simulation Expert

Andre Schäfer

Ultramid® Advanced Expert

Ekaterina Troussard

Plastic Additives

Gazi Tuerkoglu

Plastic Additives

IrgaCycle™, Recycling

Oliver Reich

Plastic Additives

IrgaCycle™, Recycling

Raphaël Dabbous

Plastic Additives

Marina Leed

Plastic Additives

Sustainability, VALERAS™, IrgaCycle™

Rainer Xalter

Plastic Additives

Automotive, IrgaCycle™

Jean-Roch Pauquet

Plastic Additives

Cinzia Tartarini

Plastic Additives

Additive for TPU

Zach Dowling

Plastic Additives

Sustainability, VALERAS™, IrgaCycle™