Performance Polymers

A second life for plastics: How Elastollan® RC is driving circularity

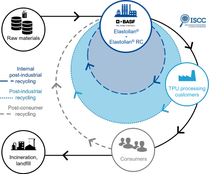

At BASF, sustainability is more than a goal – it’s a mindset. With Elastollan® RC, we’ve reimagined how thermoplastic polyurethane (TPU) waste can be transformed into high-performance materials again. Through mechanical recycling, we’re not just reducing waste – we’re creating new value.

From waste to high-performance material

Elastollan® RC is made using post-industrial TPU waste that is mechanically recycled. The material is collected, sorted, shredded, and reprocessed – without altering its chemical structure.

At BASF, we don’t just recycle – we upcycle. Unlike chemical recycling, which requires breaking down polymers into their base components, mechanical recycling retains the polymer structure. Elastollan® RC could consist of up to 100 % recycled content depending on the grade – while the mechanical properties remain stable and reliable. This makes it ideal for clean, sorted waste streams – especially post-industrial waste from production processes.

Through controlled processing and formulation expertise we elevate the value of the recycled material. This approach reduces waste but creates an alternative to fossil-based TPU, supporting circularity and performance.

BASF expands Elastollan® RC production

To scale up this initiative, BASF is investing in a dedicated production line for recycled TPU. Located in Lemförde, the facility will process both internal and customer waste, transforming it into new Elastollan® RC grades.

Empowering sustainable construction through transparent emission data

Select Elastollan® RC grades are produced under ISCC+ (International Sustainability & Carbon Certification) certified conditions, ensuring traceability and compliance with international sustainability standards. This gives customers confidence that their materials are not only high-performing but also responsibly sourced.

Mechanical recycling in action: How BASF reprocesses TPU waste into virgin Elastollan®

One example: a customer in the footwear industry returns its TPU production waste to BASF, where it is mechanically recycled and processed into new Elastollan® RC grades. These grades are then used in the customer’s next product line – closing the loop and turning waste into value.

.png)

Unlock sustainable performance: explore Elastollan® RC for your business goals

Discover how Elastollan® RC can help your business meet its sustainability goals without compromising performance.

Visit Upcycling Elastollan® or consult with an expert to learn more.