Performance Polymers

Welion & BASF Unveil the Next-Gen Solid-State Battery

Breaking Barriers:

Welion & BASF Unveil the Next-Gen Solid-State Battery

Powering the Future, Safely and Efficiently

The EV revolution is moving fast, but batteries remain a sticking point. Traditional lithium-ion batteries use flammable liquid electrolytes, which can raise safety concerns and add extra weight. These issues have long stood in the way of making electric vehicles safer, lighter, and more efficient. The industry has been searching for a solution that combines top performance with peace of mind.

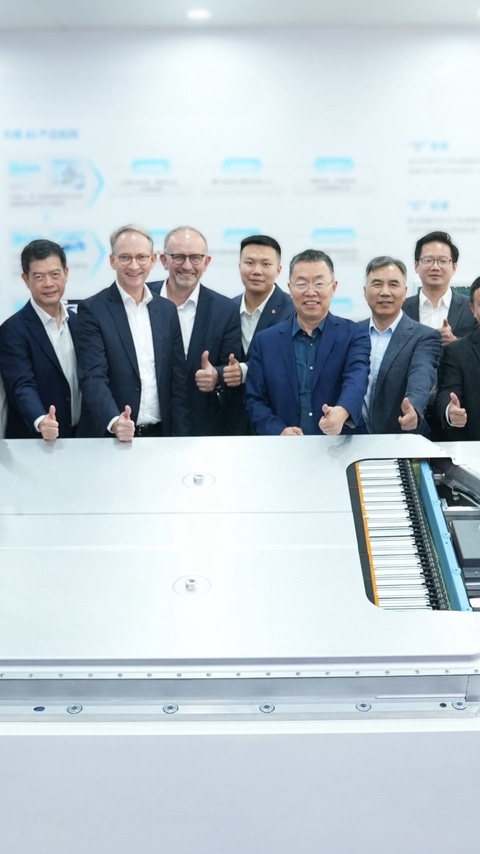

That’s where Welion New Energy Technology and BASF come in. At the 23rd Guangzhou International Automobile Exhibition, we introduced a next-generation solid-state battery pack and a big step forward in materials science and engineering.

BASF’s advanced engineering plastics Ultramid® and Ultradur® and polyurethanes Elastolit®, Elastoflex®, Elastan®, and Eastocoat® play a key role. These materials help reduce battery weight, improve thermal management, and enhance safety. The new pack includes:

- Flame-retardant cell holders for better electrical insulation

- Fire-resistant compounds in high-voltage busbars, outperforming traditional materials

- Foaming potting adhesives and fire-protection coatings to resist thermal runaway

All of this meets China’s strict GB 38031 standard and aligns with global safety benchmarks.

In the highly competitive EV battery market, innovation is a key differentiator. Solid-state batteries are the future of power and energy storage—delivering superior efficiency and safety. By combining BASF’s advanced materials with Welion’s R&D expertise, we’ve co-developed a next-generation solid-state battery pack that strengthens competitiveness and drives sustainable growth for the new energy vehicle industry.

The Result? Lighter, Safer, Smarter EVs

The numbers tell the story: BASF’s Ultramid PA side cooling plates and Eastoflex PU battery covers cut weight by about 50% compared to metal alternatives. That means more range, less energy wasted, and a smaller footprint. Elastan low-density adhesive keeps the structure strong without adding bulk, while extra polyurethane and polyurea coatings boost impact resistance.

Andy Postlethwaite, Senior Vice President, Performance Materials Asia Pacific, BASF, summed it up: “We constantly advance our portfolio with our material innovation expertise to meet dynamic regulatory demands and support our customers and automotive OEMs in their green transformation.”

The Road Ahead

With this next-gen battery pack, Welion and BASF are helping push the EV industry toward a future where safety, efficiency, and sustainability go hand in hand. The journey to greener, smarter mobility just got a major boost and the finish line feels closer than ever.

Consult with an expert

Self-service solutions: