Basotect® Offers You Many Advantages

- High sound absorption capacity

- Good thermal insulation properties

- Low weight

- Abrasiveness

- Flame resistance – without the addition of flame retardants

- Constant physical properties over a wide temperature range

Performance Polymers

Sound absorption, fire resistance, thermal insulation or abrasiveness: Basotect® combines many requirements for high-performance foam in one product. In construction and industrial applications, in the automotive and transportation sectors, but also in consumer applications, Basotect® provides a great variety of options.

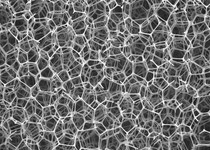

Basotect® is a flexible, open-cell foam made from melamine resin – a duroplastic synthetic material. A typical characteristic is the intricate spatial mesh structure that is formed by thin ribs that can therefore be bent into shape easily. Basotect® has excellent sound absorption properties, a low weight, high temperature resistance and low flammability.

Basotect® allows significant acoustic improvement in, for example, restaurants, reception areas, meeting rooms, and airplane cabins. However, Basotect® is not only the ideal solution for acoustic insulation. With its very good thermal insulation properties and easy processing, Basotect® also impresses with respect to thermal insulation and air conditioning technology.

In automobile manufacturing, Basotect® can be pressed into precisely contoured components, and thus offers optimum sound proofing. At the same time it can also function as a thermal shield in the engine compartment, for example.

A very different application option can be found in everyday life: With its flexible micro structure and gentle, abrasive effect, Basotect® effortlessly cleans tiles, glass ceramic stove tops, and stained wallpaper ‒ without the additional use of additional cleaning agents. Furthermore, you are using a product that was tested for harmful substances, because Basotect® W is certified to the STANDARD 100 by OEKO-TEX® (10.0.74938 HOHENSTEIN HTTI).

Discover Basotect® Dark EcoBalanced, the first dark version of BASF’s established melamine resin foam! The industry-first combines the excellent acoustic and safety properties of Basotect® B EcoBalanced with a homogeneous dark color - enabling elegant and visually striking acoustic concepts that complement contemporary color trends. Designed for sound absorption applications in building and construction (B&C), Basotect® Dark EcoBalanced enables customers to differentiate their sound absorption products by combining well-being and safety with design freedom and a reduced CO₂ footprint. The dark melamine resin foam is part of the Basotect® EcoBalanced product family.

As the world’s first melamine foam, Basotect® EcoBalanced helps to reduce the Product Carbon Footprint (PCF) of many sound absorption applications in the transportation as well as in the building and construction industries – from engine covers to wall and ceiling sound absorbers, HVAC parts and air cleaners.

Basotect® EcoBalanced has an up to 50% lower PCF than the respective BASF standard grades because of these two sustainability advantages:

BASF also offers its customers transparency by providing reliable PCF data to support them in evaluating their own products and achieving their sustainability targets.

BASF has now developed a new grade of its melamine resin foam Basotect®: It is called Basotect® C - a cold-flexible foam for durable and energy-efficient insulation of cryogenic applications. Its unique property profile makes it the ideal material to insulate LOX and LNG pipes, tanks and gas treatment machinery:

► Constant mechanical properties over a wide temperature range – and so a reliable alternative to commonly used materials for insulating gas treatment plants of liquid oxygen, nitrogen and natural gas.

This unique insulation foam for cryogenic applications by BASF helps to ensure tightness, energy efficiency, durability and safety for the treatment, storage and transport of liquefied gases!

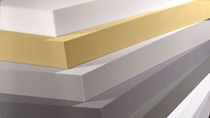

The light gray product variant is called Basotect® G+ and is equal to the white Basotect® B regarding thermal conductivity, flame retardancy and simple, mineral fiber-free fabrication. Its coloration makes it less sensitive to soiling, which also makes Basotect® G+ especially suitable for many construction and industrial applications.

The pure-white Basotect® cleans efficiently and is certified to OEKO-TEX® Standard 100 in product class I. Because of its slightly abrasive properties, Basotect® W is used as a household cleaning eraser. It is used without additional cleaning agent and works like a soft sandpaper. When moistened with water, the foam slides easily and so can remove heavy dirt on a variety of surfaces such as tiles, ceramic stove tops, ceramics, doors, leather seats and hubcaps.

Basotect® B is a high performance material especially designed for visible interior applications where it takes advantage of its full potential. The flame resistant foam combines excellent sound absorption and high light reflection.

Various options in shaping and coloring opens up a great freedom of design. Hence, Basotect® B provides functionality and enables creative acoustic and optical interior designs.

Basotect® UL has an impressive ultralight weight and is thus especially well-suited for all applications that call for a low weight, for example, in aviation and aerospace.

Special technical applications that call for the thermoforming of Basotect® can be manufactured with Basotect® TG. Its dark gray coloration makes it a material of choice in automotive construction.

The gray Basotect® UF+ is characterized by a very high elasticity and by improved fire properties, which makes this elastic version of Basotect® suitable for the construction industry and rail transportation, providing much greater freedom of processing and design.

Proven in practice: These case studies demonstrate the successful use of Basotect® in customer projects.

Basotect® is supplied in the form of foam blocks to processors for further processing. This is where the product is cut into multi-dimensional shapes by slitting, milling, sawing and stamping to form the required contour. The elastic resilience of panels made of Basotect® also allows the use of shaped cutting.

Processing Notes

Processing of any semifinished products, like Basotect®, by e.g. cutting or sawing can lead to dust formation. Any dust that might be produced during certain processing steps should be removed by vacuum directly at the cutting site. Wearing a dust mask during these tasks is recommended. Unlike products based on fibres, Basotect® is an open-cellular foam. Basotect® is therefore not associated with any irritating effects caused by the release of fibers, and so there is no need for additional safety measures during handling and transportation.

Due to the absorption behavior of melamine resin and the open-cell structure of the foam, the moisture content of the material changes with the ambient conditions. This is associated with changes in dimensions that occur similarly in the case of wood, concrete or clay tiles. This behavior must be taken into consideration during processing. The foam blocks, which are delivered sealed in PE film, must be unpacked and stored for several days prior to processing under atmospheric conditions corresponding to the blocks’ later use.

Self-service solutions: