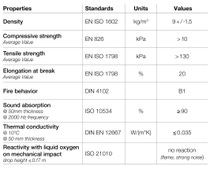

• Very good insulation up to -196°C

• Outstanding flexibility even at very low temperatures

• Very good dimensional stability at changing temperatures

• Excellent flame retardance (B1 according to DIN 4102)

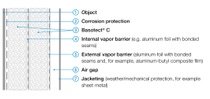

• Easy and tight installation with vapor barriers