Performance Polymers

Cellasto® reduces NVH in automotive powertrains

Raise your vehicle’s performance to the next level by incorporating Cellasto® into your powertrain components. Powertrain dynamics are one of the largest sources of noise, vibration and harshness (NVH), so using a superior, resilient and durable material is a must for maximizing power transmission while improving comfort. When you apply this highly versatile microcellular polyurethane elastomer to your mounts, bushings, and couplings, it not only accomplishes that, but it also stabilizes your drivetrain to ensure elevated performance that lasts.

Why Cellasto® is the most effective stabilization and NVH material for automotive powertrains

Design with Cellasto® to stabilize and control your drivetrain movements and maximize power transmission. With this high-performance material’s unique spectrum of qualities, you can reach your automotive performance goals with custom solutions for powertrain components.

Overall NVH improvement

Absorb a wider range of impact forces and vibrational frequencies to ensure greater efficiency and a smoother ride

High pre-load capability

Achieve the same energy absorption in a tighter space with high volume compressibility, low lateral expansion, and minimal compression set

Dynamic stiffness

Improve alignment and stability with consistent stiffness through a wide range of frequencies

Static stiffness

Provide your drivetrain with greater protection from torsional stress and strain

Lightweight

Reduce weight for the same performance up to 35% relative to conventional elastomers

Durable

Provide lifelong powertrain performance with excellent abrasion resistance to mechanical and chemical wear

Highly customizable

Select from a range of material densities to produce an endless variety of components in different shapes and sizes with this dynamic material

Global experts

Co-create competitive solutions with BASF’s global team of experts to meet your specifications with a fast turnaround time

Powertrain applications

Engineer with Cellasto® to master the extremes of torsional and loading forces in high-performance powertrains. Utilize its unique array of outstanding characteristics to combine high automotive power with the excellence of a smooth and comfortable ride.

Motor mounts

Absorb the sudden torque variations and vibrations of electric motors and combustion engines using Cellasto® motor mounts. Key to reducing powertrain wear and improving operator comfort, motor mounts made of this dynamic material are durable and resilient.

-

Tune energy absorption across the broad range of frequencies and amplitudes associated with various engine speeds

-

Maintain lasting performance with resistance to oil and grease

-

Achieve weight reduction without giving up load capability

-

Provide lifelong NVH and motor protection with excellent resilience, as well as outstanding chemical and abrasion resistance

-

Design smaller, lighter solutions that make full use of limited available space

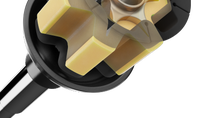

Torsional couplings and dampers

Use Cellasto® in your torsional couplings to provide superior protection for your drivetrain components from resonant and transient dynamic overloads. Achieve smoother power delivery with the outstanding NVH qualities of this high-performance material.

-

Dramatically improve NVH performance with amplitude-dependent damping

-

Tune driver experience using a variety of formulations for drivetrain components

-

Integrate damping adjustment using the extensive pre-loading capability of Cellasto®

-

Achieve better alignment compensation, thanks to optimal rotational angle properties

-

Save cost and weight

Bushings

Bushings made with Cellasto® can be compression loaded to provide superior NVH — even for the increased drive torques of high-performance vehicles. This unique material’s uniform responsiveness to demanding conditions results in smoother power delivery than with conventional materials.

● Optimize deflection associated with powerful acceleration and deceleration

● Achieve greater stability and alignment with smaller components

● Reduce component weight without compromising performance

● Improve NVH by damping a wider range of unwanted resonant frequencies

● Control higher power with greater ease and reliability

● Transmit power more effectively in demanding conditions