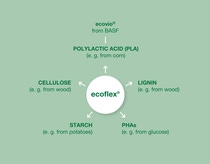

The certified compostability of the bioplastic ecoflex®

Thanks to its special chemical structure, ecoflex® can be biodegraded by microorganisms and their corresponding enzymes. Under the circumstances in an industrial composting plant, the ecoflex® molecules are biodegraded within a few weeks. In special certification procedures, independent institutes test the suitability of bioplastics in terms of biodegradability, compostability, compost quality, and plant compatibility.

ecoflex® offers various product grades that meet international and national standards for industrial composting: