Key Advantages of Elastoshore®

- Excellent thermal insulation values

- Corrosion resistant

- Mercury-free

Performance Polymers

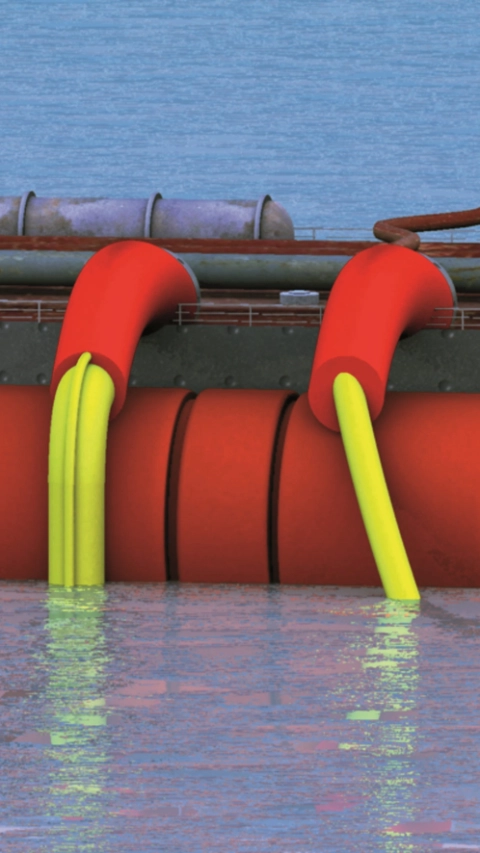

Elastoshore®’s excellent thermal insulation values, its corrosion resistance and enormous durability make it suitable for perfectly stable pipeline connections. Even under extreme conditions in the deep sea, for bend stiffeners, strakes, field joints, bend restrictors and cable protectors.

Elastoshore® GSPU products are perfect for the wet insulation of ultra-deep flowlines and subsea structures. This high performance material is reliable under the extreme stress and temperatures of the deep sea. BASF Elastoshore® is the record holder for the deepest use of GSPU at depths over 2900m.

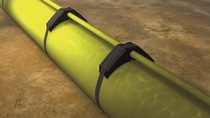

Elastoshore® field joints ensure stable protection and insulation of pipeline welds, are mercury free and specifically designed for the harsh environment of the sea. They offer excellent thermal insulation values and are corrosion resistant.

Elastoshore® structural support elastomers have various uses in the subsea industry and are used to make pipelines and jumpers. The industry has a high demand for a mercury-free solution for the pipeline strakes and Elastoshore® products surpasses 70-ton S-Lay stinger tests and meets the requirements.

Elastoshore® elastomers are also available for bend stiffener and bend restrictor applications.

The applications are as manifold as its product properties: Explore the various application possibilities of Elastoshore®!

We offer our customers a comprehensive range of services with leading technologies and products. Find the service that matches your needs!

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

Self-service solutions: