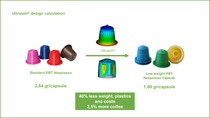

Ultradur® B1520 FC R01 at a glance:

- Easy flowing PBT grade

- Food contact approved

Excellent barrier properties:

OTR: 24 cm³ 100 μm / (m² d bar)

WVTR: 2,5 g 100 μm / (m² d 85% r.H.)

MVR: 110 cm³/10 min

- High rigidity and strength

- Chemical resistance

- High stiffness suitable for thin-walled parts

- Outstanding dimensional stability under heat (up to 200°C)