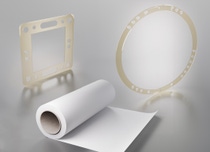

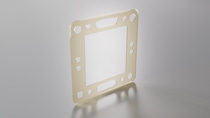

- Exceptional chemical resistance even at elevated temperatures: suitable for AWE, PEM and AEM electrolyzers

Your benefits with Ultrason®

- Exceptional chemical and high-temperature resistance

- Design freedom due to thermoplastic processing

- Lower weight electrolyzers via metal replacement

- Stable membrane casting due to high and stable material quality

- Well-founded processing knowledge for efficient part design process