Mass Balance

- Reduced PCF

- Attributed recycled content

- Saving fossil resources

- Drop-in solution

Performance Polymers

At each production step, every product adds more greenhouse gas emissions to its own backpack that is carried over along the value chain.

On #OurPlasticsJourney, we aim at improving how products are made. Discover how!

____________________________________________________________________________________

These products offer a tangible and cost-efficient sustainability improvement. They are a good first step in any sustainability strategy!

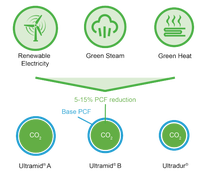

Green Energy Manufacturing entails the use of renewable electricity, green steam and heat. We can use each of these tools to reduce the base PCF to achieve very specific PCF values to answer your needs:

____________________________________________________________________________________

Self-service solutions: