Performance Polymers

Ultrasim® Material Modeling and Data

The core of Ultrasim® is a database of profound material models and simulation data for an extensive range of BASF's product portfolio, including Ultradur®, Ultramid®, Ultraform®, Ultrason®, Elastollan®, Elastolit® and more. These data are utilized for both process and structural simulations, enabling accurate predictions of material behavior.

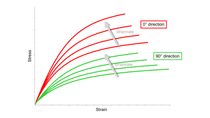

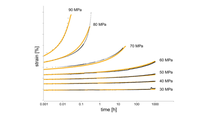

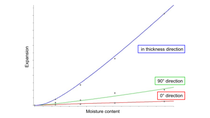

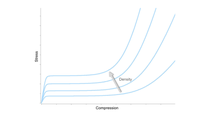

Ultrasim® also provides specialized material models for specific applications, such as fatigue, creep, cyclic loading, thermo- and moisture mechanics, ensuring comprehensive analysis for various scenarios.

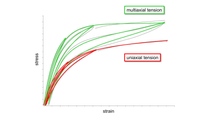

When we perform material modeling, we always follow an integrative simulation approach. This integrative approach acknowledges the notation that the performance of a polymeric material in the final part depends on the material processing during part production. This is crucial for an accurate simulation of short fiber reinforced plastics (SFRPs) and foams in structural load cases.

Ultrasim® Specialized Material Models

Ultrasim® provides specialized material models for specific applications and ensures a comprehensive analysis for various scenarios.

Consult with an expert

Self-service solutions: