Performance Polymers

Ultrasim® – CAE Competence for Your Innovative Components

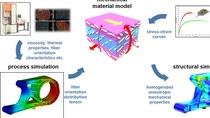

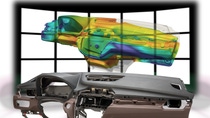

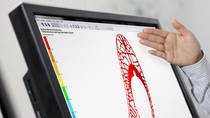

Ultrasim® is the versatile and flexible CAE competence for your innovations using BASF plastics. Our calculation of component concepts on a virtual basis starts with appropriate materials and adequate material models, ranging from the virtual prototype and ideal manufacturing process to the finished mass-produced component.

What is Ultrasim®?

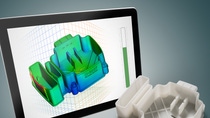

With Ultrasim® you can tailor your components for specific requirements – for efficient, lightweight components subject to high levels of stress and for your long-term market success.

The Building Blocks of Ultrasim®

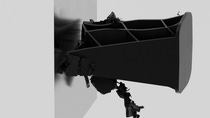

The modern calculation of thermoplastic components makes high demands on the developer. In the context of manufacturing process, part geometry and material only an integrated approach can lead to the ideal component.

Plastics reinforced with short glass fibers in particular have anisotropic properties depending on how the fibers perform in injection molding. Modern optimization methods support the part design and can improve it in every phase of its development. A completely new numerical material description can take into account the typical characteristics of the plastic in the simulation.