Performance Polymers

PPAssion for perfection

The Ultramid® Advanced portfolio:

We provide the PPA you need.

For lightweight and high-performance parts to be used in many different applications – from the automotive and the E&E industries to mechanical engineering and consumer goods: the new polyphthalamide (PPA) portfolio by BASF:

Six PPA polymers with about 50 compounds:

- Ultramid® Advanced N (PA9T)

- Ultramid® Advanced T1000 (PA6T/6I)

- Ultramid® Advanced T2000 (PA6T/66)

- Ultramid® T KR (PA6T/6)

- Ultramid® T7000 (PA/PPA)

- Ultramid® T6000 (PA66/6T)

PPA Product Selector

The right material for the right part: choose the suitable material for your application!

The PPA portfolio is globally available. It is supplemented by BASF's simulation tool Ultrasim® and our profound experience in application development. So you can find the right material for the right part with a matching, tailor-made application profile.

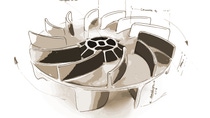

Experience how our Ultramid® Advanced portfolio proves its worth

in different industries

The PPA portfolio by BASF – all advantages at one glance

- The portfolio includes grades for injection molding and extrusion for easy and stable processing.

- Grades with or without flame-retardants are available.

- They are supplied from uncolored to laser-markable black.

- The products are equipped with different heat stabilizers.

- Due to their partially aromatic chemical structure all types offer good to excellent mechanics at elevated temperatures.

- Their hydrophobic nature allows them to withstand humidity and contact with challenging media and at the same time to maintain their strength.

- The low water uptake results in a high dimensional stability of the plastic parts in humid environments.

- They keep their strength also in lead-free soldering processes more and more often used in the electrical and electronics (E&E) industry.

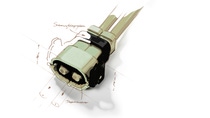

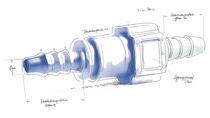

New: BASF expands its polyphthalamide offering in Europe

On February 1, 2022 BASF will start marketing several PPA grades in Europe that it acquired as part of the takeover of Solvay’s PA66 business (former Technyl® brands). Contact us and benefit from an extensive plastics portfolio including Ultramid® One J, a PPA based on PA66/6T with very good mechanical and dielectric properties under humid conditions and elevated temperatures. For the development of innovative plastics solutions, for example for E&E applications like connectors and circuit breakers, for consumer and household electronics, and for autonomous driving and emobility.

The five PPAs – overview:

Precise part design with Ultrasim® for PPAs

BASF’s simulation tool Ultrasim® is used in the design of parts for all industries. With customized models, BASF has further developed the calculation tool in such a way that parts made of Ultramid® Advanced grades can also be simulated. Using Ultrasim®, the physical behavior of the part can be predicted on the basis of manufacturing parameters, fiber anisotropy and load direction or speed. The mathematical part optimization can furthermore provide the best possible design under the given conditions. Ultrasim® is therefore a unique tool for optimizing customer parts at a very early stage so that they can handle highest loads. With these precise predictions, costs and time associated with prototypes or extensive mold corrections can be avoided.

In-depth know-how in application development

With its long experience as well as its technical and material expertise of engineering plastics, BASF can contribute to realize challenging applications and provide the most efficient technical solutions for PPA applications across all industries. Emerging trends in the markets result in challenges that need intensive joint discussions and learnings. BASF has the experts to engage with the relevant experts at processors, manufacturers and OEMs and thus to provide extensive information on materials, consultation on new application development and technical service for processing.

Our Products

Consult with an expert

Self-service solutions: