- High heat deflection temperature

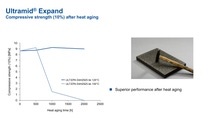

- High temperature resistance

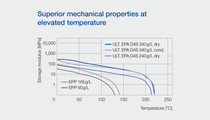

- Excellent mechanical properties at temperature >120°C

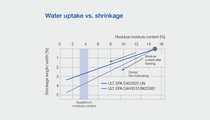

- Chemical resistance against automotive liquids

- Drop-in solution in EPP tooling (steam chest molding)

- Recyclability

- Simulation models available

- Processable via e-coating

Automotive

Ultramid® Expand – Expand your ideas!

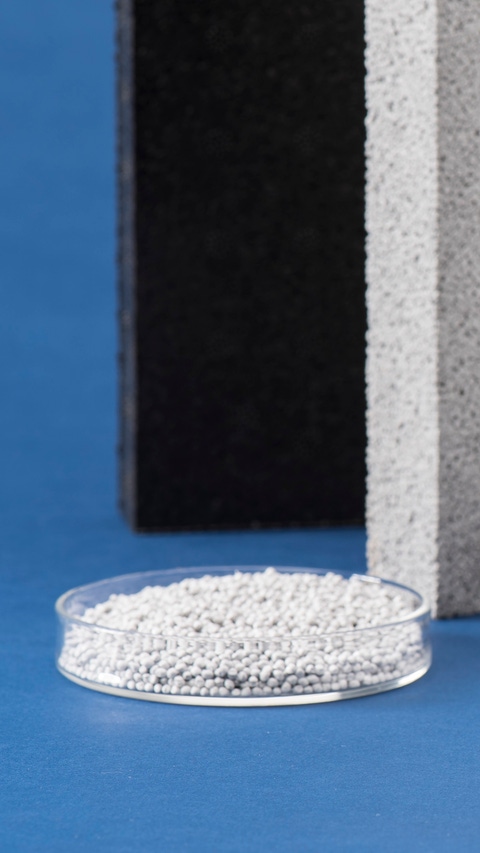

Different bead sizes that fit your requirements: 1-3 mm

Ultramid® Expand

Ultramid Expand® is a particle foam by BASF that is based on a combination of several polyamide 6 grades. The particle foam consists of pre-foamed particles with a defined particle size and density, which can be welded into a 3D component without generating foam waste in a molding machine. The component has isotropic foam properties, i.e. the same mechanical properties in all directions. A chemical reaction does not take place in the foam.

The particle foam excels with a wide range of unique characteristics: high temperature-resistance, outstanding stiffness and strength as well as an excellent chemical resistance, e.g. in contact with fuels, oils and lubricants. Additionally, the closed cell foam structure offers an exceptional compressive strength, a requirement for the use in crash relevant components that are exposed to high mechanical demands. Because of this versatility, lightweight applications are possible as well.

BASF continues its long tradition of developing particle foams. We started this project in close co-operation with our customers and now they are able to successfully produce various parts. The material can be effortlessly processed on conventional EPP-molding machines as well as with innovative water steam free technologies.

BASF’s Ultramid® grades are molding compounds on the basis of PA6, PA66 and various co-polyamides such as PA66/6. The range also includes PA6/10 and semi-aromatic polyamides. The molding compounds are available unreinforced, reinforced with glass fibers or minerals and also reinforced with long-glass fibers for special applications. Ultramid® is noted for its high mechanical strength, stiffness and thermal stability. In addition, Ultramid® offers good toughness at low temperatures, favorable sliding friction behavior and can be processed without any problems.

Technical features

Simulation

Support for application development is a key competence of BASF Simulation Engineering. Whenever necessary, numerical methods are used to predict processability and final performance of a part. This enables a complete virtual design optimization before any tool is built.

Consult with an expert

Self-service solutions:

.jpg)