• Same material performance as standard ecoflex® F Blend C1200

Performance Polymers

ecoflex® biomass balance

Go circular with ecoflex® BMB!

One step closer to circularity: the first PBAT with 100 % attributed renewable feedstock via certified biomass balance (BMB) approach.

Certified compostable biopolymer where fossil-based feedstock is replaced with waste-based biomass at the beginning of the value chain.

Advance a circular economy

Increase the use of renewable feedstock and reduce the PCF of your products with biomass-balanced ecoflex® (PBAT)!

An industry-first

• For ecoflex® F Blend C1200 BMB, fossil raw materials are replaced with renewable feedstock from organic waste at the very beginning of the value chain and attributed via a certified biomass balance approach (BMB) 1).

• New ecoflex® F Blend C1200 BMB has 60 % lower Product Carbon Footprint (PCF) 2) than the standard ecoflex® F Blend C1200.

Easy drop-in solution

Your sustainability advantages

• Rely on the same high quality of ecoflex® F Blend C1200 to which you are accustomed!

• Differentiate your products from competition by extra sustainability benefits!

• Take a decisive step towards your company’s NetZero targets!

• Contribute to the reduction of fossil resource consumption and greenhouse gas emissions!

BASF addresses your need for reduced Product Carbon Footprint (PCF)

How does ecoflex® BMB work?

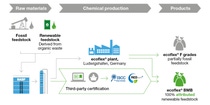

• The fossil raw materials that are usually used in the production process are replaced with renewable feedstock at the beginning of the value chain.

• The renewable feedstock comes from organic waste and residual biomass.

• The renewable feedstock is attributed to the ecoflex® grade via a mass balance approach which is certified according to REDcert2 and ISCC PLUS 1).

Different feedstock options for ecoflex® – you have the choice!

ecoflex® F: partially made with fossil feedstock

ecoflex® BMB: 100 % attributed renewable feedstock from waste and residual biomass, produced in Ludwigshafen, Germany

1) REDcert2 and ISCC PLUS are sustainability certification schemes for the use of sustainable biomass as raw material in the chemical industry. A certification according to these certification schemes confirms that the biomass used is sustainable and has been fed into the production system in the required amount. It also confirms that the sustainable biomass has been correctly attributed to the corresponding sales products. The certifications are awarded on the basis of on-site audits conducted by independent auditors.

2) BASF’s product carbon footprint (PCF) calculations for conventional products follow the requirements and guidance given by ISO 14067:2018. A TÜV Rheinland methodology review has certified that the SCOTT PCF methodology developed and used by BASF SE is based on scientific evidence, meets ISO 14067:2018 and the Together for Sustainability PCF policy, and reflects the state of the art (ID no. 0000080389: BASF SE – Certipedia). TÜV Rheinland also confirms that the biomass balance (BMB) PCF calculation method and the associated PCF reduction for BMB-certified products follow the conventional LCA method in accordance with ISO 14067 and the Together for Sustainability (TfS) policy.

Consult with an expert

Self-service solutions: