Automotive

Cellasto® reduces NVH in the automotive body

In automobiles, the body takes a beating. From potholes in the road to vibrations between internal touchpoints, there are many opportunities for noise, vibration and harshness (NVH) to transfer from the vehicle to your customer. Create a noticeably smoother, quieter driving experience by using Cellasto® in automotive body components. This versatile microcellular polyurethane elastomer efficiently reduces NVH, regardless of the origin.

Select a state-of-the-art material for the automotive body

The dynamic nature of Cellasto® allows it to serve a broad range of purposes in the body of automobiles. Its physical properties can be isolated and used to enable you to design custom-made solutions to NVH challenges, whether your product is a sleek sports car or heavy-duty truck.

High volume compressibility

Able to fit within tight spaces with low lateral expansion, resulting in a lighter vehicle that require smaller components and low compression set over the lifetime of the vehicle

Damping of high load impacts

Vibration control for high amplitudes uniquely combined with complementary cushioning for low amplitudes, all in one material solution

Noise isolation

Control noise from road surfaces, body contact, and metal-to-metal contact with a variety of damping and isolation solutions

High elongation

Avoid costly cracks and breaks resulting from harsh impacts when you incorporate this highly flexible, resilient material

Dynamic stiffness

Vehicles run smoothly and handle easily with an adjustable load deflection curve. These favorable stiffening properties can be used for a variety of applications

Durability

Protect the structure while also ensuring continuous, lifelong performance with excellent abrasion and stress resistance

Design freedom

Expand the scope of your innovations with custom variations that allow for a range of material densities, shapes and sizes

Global experts

Gain value when you co-create with BASF’s team of global engineers, designers and specialists who work with you on challenging specifications and tight deadlines

Body applications

The varsatility of Cellasto® allows it to be used in a wide variety of applications related to the car body, including both small and large components that can be made entirely out of this high-performance material, or in combination with another material. Because of its superior ability to absorb kinetic energy and dampen vibrations, your automobiles will operate with greater efficiency while delivering a smooth, quiet ride.

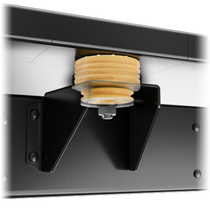

Mounts for unibody passenger vehicles

Automotive body mounts made with Cellasto® reduce NVH from road surfaces

-

Use in dampers for doors to avoid the harsh sounds of metal-on-metal

-

Lighter weight parts make the car more fuel-efficient and easier to handle

- Isolate noise and acoustics by adding Cellasto® acoustic pads around batteries and speakers, reducing rattling or “booming” noises resulting from the transmission of vibrations from the battery box to the body

- For additional NVH reduction, you can isolate an entire subframe using Cellasto® to reduce vibrations from motor and steering mechanisms, road noise and vibrations, thereby creating a smooth, sleek ride

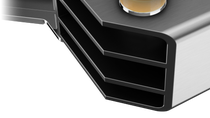

Cabin or ladder mounts for body-on-frame trucks

Trucks and commercial vehicles weather the most challenging conditions, but durable doesn’t have to mean heavy. With Cellasto®, cabin mounts are lighter and put less strain on the components attached to them while protecting the driver from NVH.

-

Reduce noise originating from the road and subsequent vibration into the cabin

-

Damp vibrations from chassis and powertrain as well as any resonance effects

-

Transfer high static loads of the body, creating a safer, more comfortable ride

-

Provide lifelong performance with excellent durability and abrasion resistance

- Reduce the overall weight of the vehicle with Cellasto® cabin mounts while gaining high energy absorption and lighter components

- Save space by reducing component height due to high compressibility and low lateral expansion behavior of the material