Automotive

Cellasto® reduces NVH in automotive chassis

Improve driving comfort by reducing noise, vibration and harshness (NVH) in automotive chassis components with Cellasto®. Load-bearing structures experience NVH from road surfaces as well as from moving parts throughout the automobile. But the special microcellular and compact polyurethane elastomers of Cellasto® efficiently manage the disturbance, no matter what the source.

Choose the superior automotive chassis material

Extend the limits of innovation by choosing Cellasto® as your single most versatile polyurethane performance material. The physical properties of Cellasto® can be isolated and manipulated through creative chemistry. This results in a broad material portfolio that can be used to develop tailor-made solutions for a variety of chassis mounts and suspension elements.

NVH improvement

Manage high loads with great efficiency to ensure a smooth, quiet ride and superior vehicle handling

High volume compressibility

Achieve maximum energy absorption in tight spaces with very low lateral expansion, allowing you to save weight and package space

Selective damping

Create vibration control for high amplitudes uniquely combined with complementary cushioning for low amplitudes, all in one material solution

Dynamic stiffness

Offer a noticeably smoother ride and ease of handling with a more harmonized stiffness curve compared to other materials

Lightweight components

Reduce weight by 30% or more

Durability

Protect the suspension while also ensuring continuous, lifelong performance with excellent abrasion and stress resistance

Custom solution

Choose custom variations that allow for a range of material densities and endless component shapes and sizes

Access to global experts

Gain value from your partnership with BASF’s team of global engineers, designers and specialists who work with you on fast turnaround times and precise specifications

Chassis applications

Created using the full range of polyurethane technologies, Cellasto® can handle even the toughest chassis loads. The customized Performance Material absorbs kinetic energy with great efficiency to manage peak loads and deliver a smooth, safe ride, particularly in the following applications:

Jounce bumper

Automotive jounce bumpers made with Cellasto® reduce NVH from road surfaces, and while braking. With this dynamic material, you can:

- Influence the load deflection curve for jounce bumpers with or without a support ring, spacer and cup

- Reduce peak loads with high energy absorption

- Create a smaller package for the shock absorber strut allowing a larger dust cover capacity

- Lower the total component cost with lighter weight and smaller packages

- Optimize component design to achieve a stiffness-optimized force-displacement characteristics that leads to optimum ride comfort

Coil spring isolator

Protect the suspension and the interfaces in even the most challenging driving environments with coil spring isolators made from Cellasto®. As a durable, quiet base for your springs, Cellasto® coil spring isolators will last the lifetime of the vehicle, preventing metal-on-metal wear, and will:

- Efficiently damp coil spring resonances for high and low amplitudes

- Reduce chassis and road-borne noise

- Provide lifelong performance with excellent durability, dirt- and abrasion-resistance

- Reduce costs when you combine coil spring isolators with an end stop or jounce bumper in one component

Damping system

Cellasto® can provide one fully assembled damping system that guarantees the perfect interaction of top mount, jounce bumper, coil spring isolator and dust cover. This will:

- Reduce complexity for the customer in the development and project management stages

- Create compatibility between single components, eliminating the need to make compromises

- Reduce packaging and cost

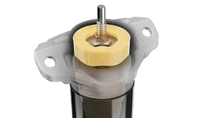

Top mount

Influence driving comfort with top mounts made from Cellasto®. Balance the connection between the shock absorber and the chassis with just the right amount of isolation to optimize NVH reduction.

- Effectively reduce dynamic wheel loads, increasing road safety

- Manage load peaks to minimize rumbling noises in the shock absorber

- Improve decoupling between the road surface and body thorugh excellent vibration and noise isolation at high and low amplitudes

- Damp inherent wheel frequency, while reducing irritating vibrations

- Gain more design freedom, reduce weight and lower costs with high volume compressibility

- Achieve excellent vibration and noise insulation readiness for high and low amplitudes

- Choose lighter aluminum inlay and eMobility with reinforced housing for cost savings designs to cover higher battery pack loads

- Access BASF expertise to develop housings in plastic materials for even more weight savings

- Achieve outstanding durability performance overall

Steering isolation

As a steering element, Cellasto® manages radial loads with its high volume compressibility, allowing you to deliver improved safety as well as superior handling for an exciting driving experience.

- Simultaneously satisfy NVH as well as vehicle handling challenges

- Reduce steering vibration on rough surfaces with efficient decoupling

- Deliver dynamic steering at any speed with ideal acoustical isolation and stiffness

- Create new coupling and bushing designs for unique automotive challenges