Automotive

Cellasto® reduces NVH for appliances

Meet consumer demand for comfort and quiet with a high-performance microcellular polyurethane elastomer that reduces noise, vibration and harshness (NVH) while delivering superior advantages over traditional materials, such as many other elastic materials.

Why Cellasto® is the innovators’ choice for appliances

BASF is your experienced partner in the home appliances industry, providing tailor-made and safety-certified components capitalizing on the extremely good dampening performance of Cellasto® by small component sizes. Count on BASF’s team of global experts to help you engineer appliances that meet precise specifications for NVH, safety and performance. Discover state-of-the-art, economical appliances solutions.

Unique applications for home appliances

The microcellular nature of Cellasto® has a significantly superior ability to reduce noise and vibrations compared to other elastomers, drastically reducing NVH while adding years to the lifetime of your products:

Washing machines

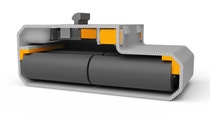

Washing machines produce some of the harshest vibrations of all home appliances due to unbalanced masses during operation. Not only is the noise from the vibrations disruptive, but it also causes wear and tear on the machine, costing customers extra money.

- Friction dampers made with Cellasto® significantly reduce NVH by efficiently absorbing energies of unbalanced masses

- Around the world, washing machine producers trust in Cellasto® friction dampers

- Due to its superior strength, machines made with Cellasto® last longer, creating a more valuable product for the customer

Dishwashers

This may be the most disruptive home appliance because it’s located in the kitchen and runs for long periods of time, creating unwanted noise in one of the most popular gathering places in the home.

- Cellasto® bearing for circulation pumps reduces NVH

- When you add Cellasto® to power and pump components, the transmission of vibrations to the outer device panels is reduced and corresponding airborne sound is limited

Vacuum cleaners

These appliances are typically so loud, it’s hard to concentrate on anything while they’re running.

- Bearing turbines equipped with Cellasto® are quieter and less disruptive

- Cellasto® wheel suspensions provide a smooth handling on hard surfaces

- Components made with Cellasto® are lightweight, making them less burdensome to use

Coffeemakers, coffee grinders & mixers

Everyone loves the smell of freshly ground and brewed coffee when they wake up in the morning or the lovely taste of fresh smoothies, but the sound of these devices is unpleasant

- With Cellasto® bearings, grinding gears or driving units, you won’t get that harsh sound associated with these appliances

- When you add Cellasto® to bearing piston pumps, you reduce the pulsing sound

Air purifiers & fans

Adding another noise-making appliance to a home, especially one that your customer expects to be silent, creates additional stress for consumers. An air purifier’s or fan’s sound should be as light as the air it is cleaning.

- Cellasto® bearing fans for air purifiers are barely audible

- Reduced vibration further reduces noise

- Air purifiers and fans made with Cellasto® components are so quiet, they won’t disrupt your customers’ lifestyle, whether they’re sleeping or reading a book

Electric shavers

The transition from sleeping to waking should be as calm and pleasant as possible, so the last thing your customers need is a noisy shaver buzzing near their ears.

- Cellasto® for bearings of electric motors increases accuracy by reducing vibrations and providing a quiet and smooth shave

- With its allowed high volume compressibility and high load capacity, Cellasto® operates within the tiniest of spaces in smaller appliances

- The noise created by cutting hairs as well as the driving unit itself will be damped by Cellasto® due to its microcellular nature

Cellasto® brings comfort and quiet to the home through home appliances performance

Your customers will quickly realize the superior quality of your home appliances made with Cellasto® components when they flip the switch on their vacuums or press the start button on their washing machines. Their home appliances will not only operate smoothly and quietly, but they will also last longer with less maintenance than those made with traditional materials.

When you co-create with BASF’s team of experts to develop custom solutions, your innovations will not only earn the reputation of having superior quality, but they will also be unique to the market.

Excellent energy absorption

Even in restricted spaces, Cellasto® ensures excellent acoustic and vibration dampening. The microcellular qualities of Cellasto® enable kinetic energy control at high and low frequencies with a single solution. The progressive load deflection of Cellasto® creates a smoother performance and counteracts resonances, bringing quiet and comfort to the customer while extending the life of the product.

Stability and strength

Avoid the cost of frequent product or parts replacement due to the time-tested resistance of Cellasto® to abrasion, heat and more. An extremely low compression set leads to consistent, life-long stiffness maintaining the designed performance for much longer.

Unlike competitors using other elastic materials, Cellasto® has excellent aging stability without the use of plasticizers, bringing a durability to home appliances components that enables innovators to create products of superior quality. The dynamic strength of Cellasto® allows appliances to fully maintain NVH performance over time.

Small installation space

The high volume compressibility and high static load capacity of Cellasto® allows you to fit appliances’ parts neatly into tight spaces. There is low lateral expansion as the microcellular material compresses, resulting in smaller, lighter appliances components that are not only more cost and time-efficient to assemble, but are also easier for the end-user to maneuver.

Good abrasion resistance

Appliance components take a beating, causing wear and tear on the elements as well as the entire machine. Cellasto® microcellular properties make it resistant to abrasions, thereby extending the life of the product.

BASF: Your global partner in appliances solutions

The Cellasto® team helps you meet the increasing demands your customers have for the appliances industry. Count on BASF as your partner for:

- Development, simulation and testing to help you refine your design

- Certified appliances components that comply with standards

- Global reach that shortens your acquisition time

- New technologies you can leverage for market advantages

- Efficient, worldwide supply chain management that ensures maximum value

- Commercial support that enhances business development and profitability

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.