Automotive

Cellasto® reduces NVH for improved heavy equipment operation

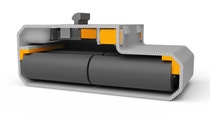

Use Cellasto® to revolutionize damping and bearing protection in heavy equipment while reducing noise, vibration and harshness (NVH). This high-performance microcellular polyurethane elastomer increases both functional ease and durability, extending equipment life and hours of safe operation.

Why front runners choose Cellasto® for heavy equipment operations

BASF is your experienced partner in the heavy equipment industry, providing custom-designed and safety-certified components crafted with the outstanding versatility of Cellasto®. Count on BASF’s team of global experts to help you engineer designs that meet your specifications for NVH, safety and performance.

Agricultural and forestry equipment

Extend the hours of safe operation with Cellasto®. Protect the cabin and driver’s seat from harmful NVH and mechanical movement with this material’s outstanding damping abilities.

Cellasto® protects various components from harsh conditions and compensates assembly tolerances of temperature variations.

Construction and mining equipment

Incorporate Cellasto® into bearing seals, tool attachments, and suspension components to make your construction and mining equipment more dependable and durable. Cellasto® offers exceptional wear resistance under gritty conditions and outstanding resilience under extended, heavy use. Through its superior qualities, Cellasto® provides greater protection of components, reducing maintenance and lengthening equipment life.

Lifting equipment

Absorb hard stops more effectively with Cellasto® in cranes, trolleys and forklifts. Superior damping characteristics increase the safety of your lifting equipment by reducing operator fatigue and the risks associated with sudden movements.

Specialized vehicles

Increase the safety of your specialized vehicles with Cellasto®. This proven material reduces the transmission of bumps, twists, and oscillations to vehicle operators with its outstanding impact absorbance. Apply it to decouple cabins and seats from engine vibration and transporter movement and to isolate batteries from threatening jerks and impacts.

Cellasto® ensures safe and durable heavy equipment operations

Engineering heavy equipment with Cellasto® amplifies its durability, extends hours of safe operation, and improves the protection of essential components. The material’s superior qualities increase NVH decoupling of cabs and batteries to better safeguard both equipment and operators.

High resistance to grit, compression, and temperature changes make Cellasto® a superior material for long lasting, dependable performance in your heavy equipment components. Discover endless possibilities when you co-create custom solutions with BASF’s team of experts.

Advantages of Cellasto® components

- High load capacity

- High compressibility

- Excellent fatigue strength

- Efficient shock absorption

- High-abrasion resistance

- Unusually versatile damping abilities over a broad range of oscillation frequencies

- Resistance to cold, heat and dirt

BASF: Your global partner in heavy equipment engineering

The Cellasto® team helps you keep pace with the high expectations of your customers. Count on BASF as your partner for:

- Development, simulation and testing to help you refine your design

- Global reach that shortens your acquisition time

- New technologies you can leverage for market advantages

- Efficient, worldwide supply chain management that ensures maximum value

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.