Automotive

Create safer, more comfortable power tools with Cellasto® NVH solutions

Our high-performing and high dynamically loadable microcellular polyurethane elastomer reduces noise, vibration and harshness (NVH) while providing more opportunities for engineering innovation over traditional materials, such as other elastomers. Give your customers the safety and comfort they need to be competitive in today’s market and moreover fulfill health and safety requirements, such as those required by DIRECTIVE 2002/44/EC for hand-guided tools.

Why Cellasto® is the trusted choice for power tools

Design a custom solution to fit your tool specifications while also meeting safety standards and providing comfort to your customers. The versatility of Cellasto® allows it to fit in the tightest of spaces to reduce NVH in power tools, regardless of shape or size.

Hammer drill & nail gun

Powerful tools don’t need to be cumbersome or dangerous to operate. Use Cellasto® to create precision tools that are easy to handle.

- Exceptionally high impacts will be effectively absorbed by Cellasto® components

- The progressive nature in deflection of Cellasto® will support users in guiding their machines and can reduce occurring resonances

- Protect the inner parts of your power tools from dust and dirt when you add Cellasto® seals

Brush cutters, hedge trimmers & motor saws

Small yet powerful, these machines can be challenging for the consumer to handle. When you add Cellasto® to guard against NVH, the impact is significant.

- Used to dampen the handle, Cellasto® absorbs not only vibration from the driving-unit but also from the cutting process

- Lighten the machine weight with Cellasto®, making these heavy hand-held machines easier to carry and use

- Friction dampers prevent the shafts of trimmers from moving down on their own, protecting the operator from the blade

Orbital sander & grinding machines

Smoothing down surfaces with a sander can be a rough experience. Use Cellasto® to smooth over consumer concerns with these benefits:

- Low dynamic stiffening, especially at high frequencies

- Improved acoustics when using Cellasto® to dampen unusual movements

- Absence of pain and numbness in the fingers after long working hours

- Better grinding results due to more flexible surface contact of the grinding discs

Oscillating knife cutter

Whether you’re cutting paper, rubber, or even wood, Cellasto® NVH components ensure a smoother operation and greater precision.

- Decoupling ability increases precision through smoother movements

- Less vibration reduces noise

Robotic lawn mower

One of the most widely used residential and commercial tools, lawnmowers with a quiet, smooth ride are sure to get noticed by the rider, yet they won’t disturb conversations on the terrace

- Decoupling of the driving unit also absorbs the vibrations coming from the cutter bar itself and ensures a quiet mowing experience

Operate efficiently and safely with Cellasto®

When added to power tool components, Cellasto® microcellular properties reduce the discomfort resulting from vibration and noise.

When you develop power tools made with Cellasto®, you’re positioning your company on the cutting edge of technology. BASF’s team of experts serve as co-creators of your unique innovations to develop the long-lasting, safe, and cost-efficient products that your customers will rave about.

Decoupling for improved NVH behavior

Power tools and the customers handling them are subject to high-speed and harsh vibratory motion. Cellasto® decouples the critical contact points and creates superior acoustic and vibration damping. The versatility of Cellasto® reduces NVH, increasing comfort and safety, even in the harshest of tools.

Insensitive yet responsive

Cellasto® isn’t affected by heat or cold. With preloads of up to 35%, Cellasto® maintains its stiffness while still being responsive to dynamic movement.

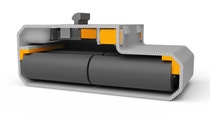

High volume compressibility & high load capacity

Unlike many other elastic materials, Cellasto® microcellular properties give it a low compression set, allowing you to fit parts into much tighter spaces. As the microcellular material compresses, the significantly reduced lateral expansion in combination with high load capacities results in very small Cellasto® part sizes. Since the compressibility makes Cellasto® a forgiving material, you can use it to handle challenging tolerances.

Flexible yet strong

The abrasion resistance of Cellasto®, superior NVH properties, and excellent aging stability-all without diffusing plasticizers- will help you create the comfort your customers need when operating hand-guided power tools. Your customers will appreciate avoiding the cost of frequent maintenance as a result of the resistance of Cellasto® to oil, dirt and dust, which shortens the life of power tools made with traditional materials. With its superb compression set for a variety of load conditions, it can be used as a sealant against dust.

BASF: Your reliable partner for innovative products

When you collaborate with a global leader in performance materials, the superior quality of your products will place your company firmly on the industry map. Count on BASF as a partner for:

- Development, simulation and testing to help you refine your design

- Certified components that comply with standards

- Global reach that shortens your acquisition time

- New technologies you can leverage for market advantages

- Efficient, worldwide supply chain management that ensures maximum value

- Commercial support that enhances business development and profitability

- Cutting edge technologies you can leverage to stay ahead of the pack

Cellasto® product groups

Cellasto® special microcellular and compact polyurethane elastomers simplify your designs to improve your value chain. Use it for NVH reduction in a variety of applications. You’ll be able to produce market-ready goods faster than before, from routine parts to forward-thinking, engineered components.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.